At 1zu1 we enable you to treat master models, duplicated parts and series parts according to customer requirements with special surface techniques. We finish the prototypes and serial parts via EDM texturing, high gloss, special effects (metallic, silver, partial) or subsequent varnishing. We are also happy to implement individual color samples or color requests (RAL, NCS, Pantone) for you.

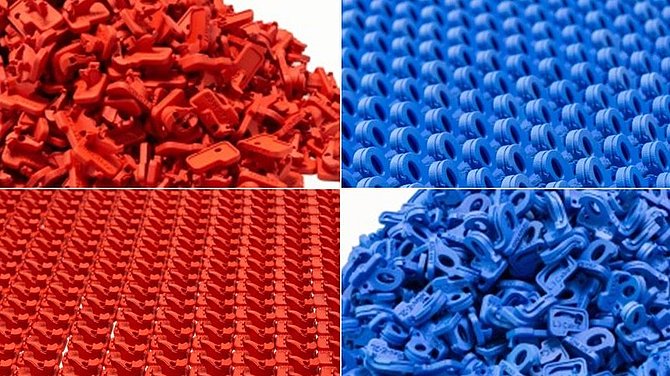

For this purpose, we offer a wide variety of surface treatment processes in post-processing, depending on the initial technology: infiltration, polishing, tumbling, printing, laser marking, vapor deposition/metallization, hot foil stamping, heatset impregnation and chemical smoothing. Each process can be applied individually, in combination, partially or fully, according to RAL or NCS.

The surfaces of prototypes and series components can be improved in further processing steps.

This form of surface treatment includes various processes and technologies that change the surface properties of manufactured components and models. This enables the improvement of surface functions of prototypes and of components in small series. For example, a coating can be applied to enhance the components by protecting them from wear and tear or corrosion. The surfaces can also be given an optical or aesthetic finish. For example, glossy lacquers, logos and much more can be applied to the components.

A key feature of surface finishing is the ability to give models and prototypes additional functions. For example, the surface can be protected against corrosion, and further enhancements can be made in terms of temperature resistance or durability.

Another advantage is optical refinement and thus the improvement of aesthetic and decorative properties. At 1zu1 we offer the following methods: infiltration, polishing, tumbling, printing, laser marking, vapor deposition/metallization, hot foil stamping and heatset impregnation.