Series parts in the blink of an eye

In a quality that meets series requirements

From plastic injection molding to additive manufacturing, our range of technologies allows you to manufacture components which are used as series parts and put into circulation. Your quality criteria, test methods and test intervals provide a common basis for success.

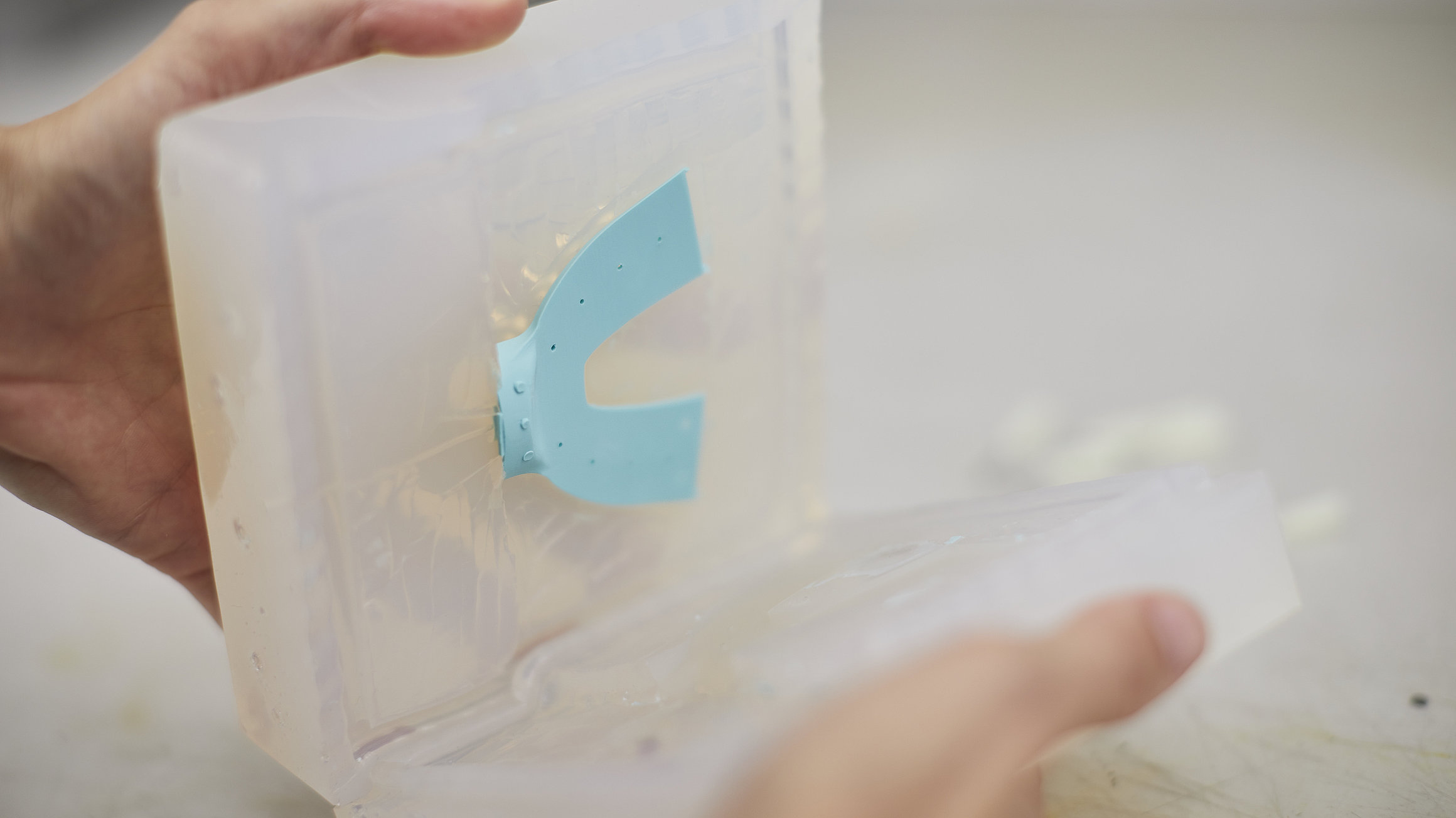

When we talk about production, we mean serialparts that are put into circulation and for which certificates, guarantees of origin or other things are available. For the production of your plastic parts, we use a wide portfolio of different technologies. Additive processes such as 3D printing (Selective Laser Sintering), injection molding and vacuum casting open the way to production in series and pre-series production.

Pre-series

Pre-series are put into circulation for the first time by the customer. Later, these are replaced by series parts. They are used for validation of a series, as final test parts for installation or for final functional tests. This should result in a release for series production with very little effort.

Series

These components, are put into circulation as series parts by our customers. The quality requirements of the customer are to be coordinated with the 1zu1 possibilities. A validation of the processes is possible.

Various additional technologies, such as chemical smoothing of laser-sintered parts or coloring of plastic parts by impregnation, bring the 3D printed parts so close to the usual series requirement from injection molding that there is no longer any discernible difference. This high level of vertical integration makes it possible to produce outstanding series 3D printed parts. However, the decisive factor is whether the series material is approved by the customer.

- Applications with a total of up to 350,000 parts in the life cycle of a plastic part

- For very small quantities of very few parts, it makes sense to select 3D printing as a production technology from the outset.

- 3D printing: quantities of up to 100,000 are possible and, depending on the requirements of the component, also useful.

By using in-house manufactured aluminum molds and the entire subsequent injection molding process, iteration steps can be completed in an extremely short time, starting from the first injection-molded prototype up to a production run of 100,000 pieces or more. You are faster on the market with your product and profit by selling your products to your customers at an early stage. At the same time, the cost of aluminum molds is only a fraction of the cost of steel molds.

- With 3D printing technologies: 2–5 working days

- With plastic injection molding: 2-7 weeks

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/4/csm_20230315_DAT_0272_1200Px_3e60b5e8c8.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/c/csm_buehler_multitherm_1200x800_1efe509fe9.jpg)