Selective Laser Sintering Fine Detail Resolution (SLS-FDR) With the laser sintering material PA11

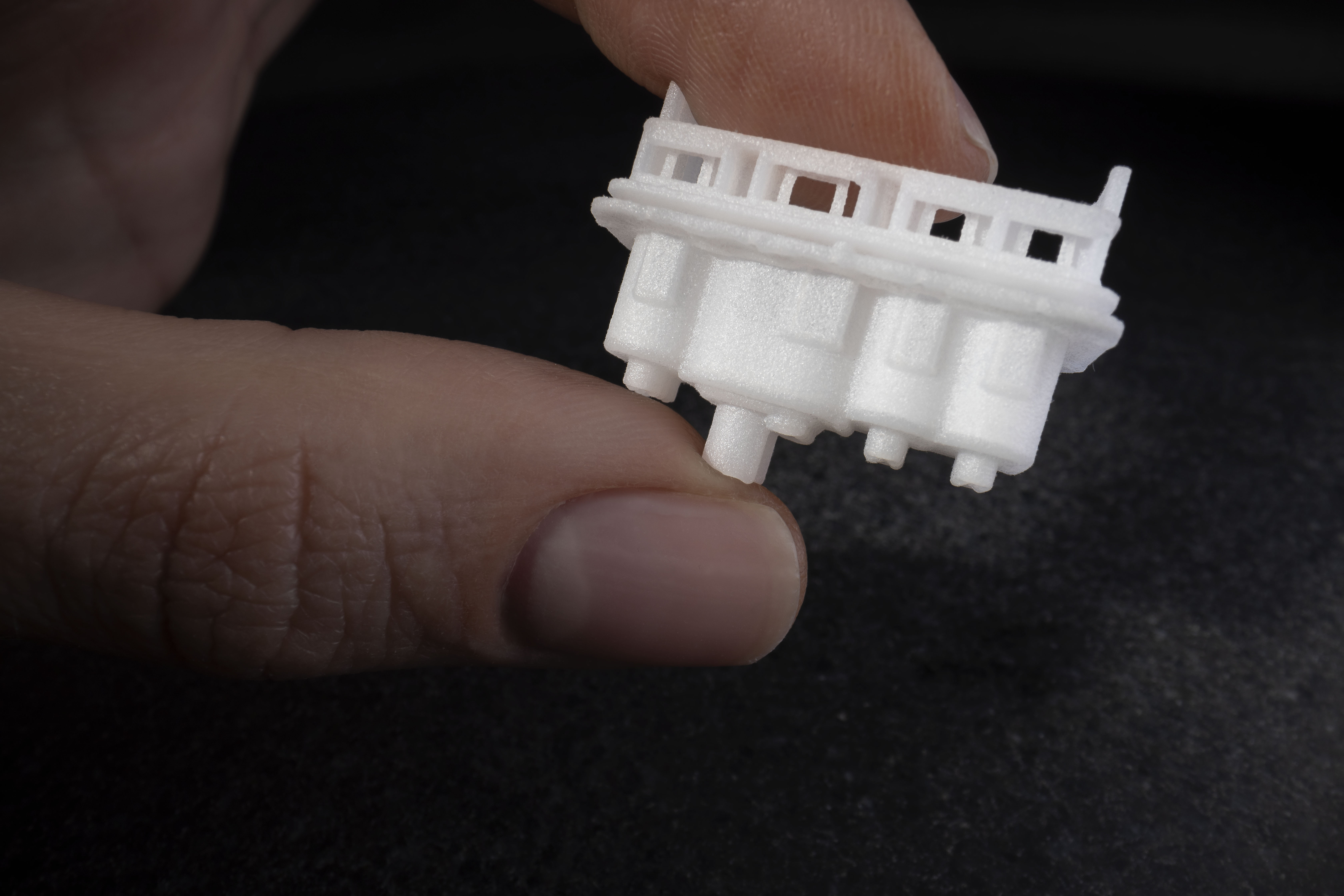

Tiny details make a big difference. Fine Detail Resolution (FDR) sintering technology from EOS enables extremely intricate structures with highly refined surfaces. And this on stable components with a minimum wall thickness of around 0.22 mm. With this world first, 1zu1 is the first user of a new technology in the world market.

The finest laser meets the right material

This process is based on three components: a laser with an ultra-fine beam, the low layer thickness and polyamide PA1101. The advantages: This plastic is particularly flexible, tough and high resolution. These properties produce the best detail imaging with smooth surfaces and excellent edge sharpness.

Not only do you benefit from high-precision prototype components, but also possible applications for series production. These range across a variety of applications. Typical examples range from filter units and fluid guides to electronic components. The tolerances achievable with FDR technology correspond to those we know from injection molding, even for the smallest parts. 50 µm and less is possible. The coordination of details is carried out individually for each customer. The component is optimized for the process to ensure that the application fits the series.

In addition, the PA1101 FDR material is insensitive to elevated ambient temperatures. This further expands the possible application areas and allows, among other things, tests during live operation.

| Polyamide EOS PA 1101 | Polyamide EOS PA 2200 | Polyamide EOS PA 3200 GF | Polyamide EOS PA 2210 FR | Polyamide ALM PA 603-CF | AM Polymers ROLASERIT® PP01 | |

|---|---|---|---|---|---|---|

| SLS-FDR | In comparison: SLS | |||||

| Hardness [Shore D] | 75 | 75 | 80 | 59 | ||

| Bending modulus of elasticity [MPa or N/mm²] | 1700 ±80 | 2900 | 2300 | 9170 | 684 | |

| Tensile modulus of elasticity [MPa or N/mm²] | 1600 | 1900 ±50 | 2850 ±350 | 2200-2500 | 7900 | 650 |

| Elongation at break [%] | 30-40 | 20 ±3 | 7 ±2 | 3-7 | 4 | 24 |

| Vicat softening temperature [°C] | 165 ±2 | 166-179 | >108 | |||

| Density [g/cm³] | 0.99 | 0.93 | 1.22 | 1.06 | 1.10 | 0.89 |

| Tensile strength [MPa or N/mm²] | 48 | 50 ±1 | 49 ±2 | 38-46 | 85 | 19.5 |

| Notch impact strength [kJ/m²] | 6.5 | 3.4 ±0.5 | 4.2 | 8.4 | 3.0 | |

| Impact strength [kJ/m²] | 35 ±8 | 21 | 31 | |||

| Glass ball weight fraction in [%] | 40 | |||||

| Flammability (ignition time 12s) | 1.7 mm + 2.0 mm Test passed | |||||

| Smoke density | 1.7 mm + 2.0 mm Test passed | |||||

| Burning behavior | 1.1 mm / HB 2.0 mm* / V-O | |||||

| Toxicity | 1.7 mm + 2.0 mm Test passed | |||||

| Appearance/color | Natural | White | Grayish | White | Darkgrey | Yellowish |

| Colorability | Excellent, not RAL | Excellent | Limited, not RAL | Possible** | Limited, only black | Not colorable |

| Chemical smoothing | Excellent | Excellent | Excellent | Possible** | Excellent | Not possible |

| Material datasheet | Materialdatasheet | Materialdatasheet (Only german) | Materialdatasheet (Only german) | Materialdatasheet | Materialdatasheet | Materialdatasheet (Only german) |

| Additional certificates | Biocompatible | Biocompatible Food contact | Food contact |

The material data have been verified by the Fraunhofer Institute or are based on the manufacturer's data sheets.

* In internal tests by the material manufacturer, UL94 V-0 was already achieved at a wall thickness of 2.0 mm. Officially (Blue Card) UL94 V-0 is confirmed at 3.0 mm wall thickness.

** Possible loss of flame retardancy.

1zu1 as a pilot partner

And the best part? 1zu1 is also a pilot partner of EOS for this groundbreaking technology. As such, we have thought ahead, tinkered and tested for you and thoroughly researched the possibilities that will benefit you.

The result is components that are even more precise and accurate than anything previously achieved by any other sintering technology for plastics. In the past, we used to say “close to the original” – now it meets customer requirements and is used for application as the original.

Your advantages

- Ideal for new applications: finest screens, small channels or individual mini components realized quickly and precisely

- Biocompatible material PA11

- Suitable for prototypes and series production with functions that are not possible in injection molding

- 5-40 mm large components with highest detail resolution

- Minimum wall thickness of 0.22 mm

- Twice as fine components as with previous SLS technologies (comparable to SLA parts)

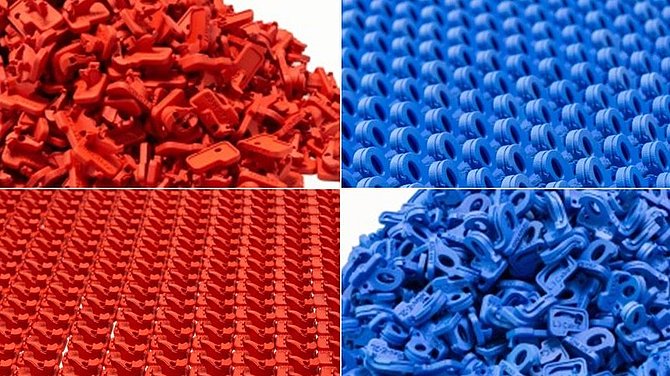

- Production quantities from one piece to 1,000 pieces

- Components with the tolerance requirements of the series

Tolerances

Fine Detail Resolution (FDR) technology - for high-precision prototypes and series part production in the SLS process. The tolerance field TG5 according to DIN 16742 can be achieved with this technology as standard from the very first component. We can guarantee you the tolerance group TG4 according to DIN 16742 if you optimize components and process together with 1zu1 in iteration steps. Details below 0.25 mm cannot be imaged.

Advice tailored to your needs

At 1zu1, we help you find the perfect solution by combining the best technology with a wide range of materials. And this is implemented in the shortest possible time and with the highest technical precision.

Challenge us. What can I do for your project?

Sebastian Mathies

1zu1sales

business developer

T +43 5572 33 333-834

sebastian.mathies@1zu1.eu

»1zu1prototyping, that's like fast food on the level of top gastronomy. And if necessary, with a lot of portions.«

Sebastian Mathies knows that the eye also eats. That's why he chooses the right ingredients, the right technology and the necessary finishing steps. The result: prototypes to your taste.

Stefan Rädler

1zu1sales

area manager Germany

T +43 5572 33 333-842

stefan.raedler@1zu1.eu

» For perfectly implemented ideas, I propose new technological paths with my customers.«

In motocross and enduro, Stefan Rädler is on difficult paths.

Klaus Pichler

1zu1sales

area manager Austria

T +43 5572 33 333-838

klaus.pichler@1zu1.eu

»As a cyclist, I know that excellent technology is the key to speed – and therefore to success..«

Klaus Pichler spends his free time in the saddle – he and his road bike conquer Austria’s mountains with endurance and the right pedal stroke.

Sebastian Mathies

1zu1sales

business developer

T +43 5572 33 333-834

sebastian.mathies@1zu1.eu

»1zu1prototyping, that's like fast food on the level of top gastronomy. And if necessary, with a lot of portions.«

Sebastian Mathies knows that the eye also eats. That's why he chooses the right ingredients, the right technology and the necessary finishing steps. The result: prototypes to your taste.

Surface finishes

Here at 1zu1 we can treat master models, duplicated parts and serial parts with special surface techniques according to customer requirements . We finish the prototypes and serial parts via EDM texturing, high gloss, special effects (metallic, silver, partial) or subsequent varnishing.

We can also accommodate individual color samples or color requests (RAL, NCS, Pantone). For this purpose, we offer a wide range of surface treatment processes in manual finishing, depending on the initial technology. Each process can be applied individually, in combination, partially or fully, according to RAL or NCS.

The possibility of individual printing, laser marking as well as hot foil stamping is also available at 1zu1 in-house. Put us to the test!

Systems

At 1zu1

we currently have 13 SLS machines for plastics with different materials at your disposal. We are constantly investing in new machine technologies. On all machines we realize build layers from 40 - 100 µm and wall thicknesses from 0.22 up to 0.65 mm. Previously visible layers disappear more and more, clean and smooth sidewalls are created, fine or large parts can be produced even more accurately. We start daily with all materials. Our standard lead times are 3 days. Larger dimensions or quantities on request.

| SLS systems | Type designation | Construction layer thickness | System construction space | Wall thickness | Materials |

|---|---|---|---|---|---|

| EOS | FORMIGA P 100 | 100 µm | 200 x 250 x 330 mm | 0.45 mm | SLS Rubber |

| EOS | FORMIGA P 110 | 100 µm | 200 x 250 x 330 mm | 0.45 mm | PA12, PA12 GB |

| EOS | FORMIGA P 110 Velocis | 100 µm | 200 x 250 x 330 mm | 0.45 mm | PA12, PA12 GB |

| EOS | EOS P 396 | 100 µm | 340 x 340 x 600 mm | 0.65 mm | PA12, PA12 GB, PA12 FR, PA 603-CF, TPU |

| EOS | EOS P 500 | 100 µm | 500 x 330 x 400 mm | 0.5 mm | PA12 |

| EOS | FORMIGA P 110 FDR | 40 µm | 200 x 250 x 125 mm | 0.22 mm | PA11 |

In the prototal group

In SLS, a wide range of different equipment and materials are available to our entire customer network. The number of 60 SLS machines is divided into 20 EOS P1xx -, 20 EOS P3xx -, 5 EOS P5xx - and 15 EOS P7xx machines. The material variety ranges from standard materials to special materials. We are proud to be part of this international group of companies.

![[Translate to English:] Selective Laser Sintering (SLS)](/fileadmin/_processed_/e/c/csm_1zu1-Ameise-Header_b3d4651210.jpg)

![[Translate to English:] Selective Laser Sintering flexible (SLS)](/fileadmin/_processed_/c/5/csm_20230607_DAT_0001_Original_5d31893bd8.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/e/csm_IMG_20220428_103448_6a076bed20.jpg)