When parts cool down, micro-cracks can form which can impair the tightness of thin-walled components. Therefore as an option, we offer “tight infiltration” of the laser-sinteredparts via an immersion process. This allows the sealant to also be applied to inaccessible areas that cannot be reached with paint.

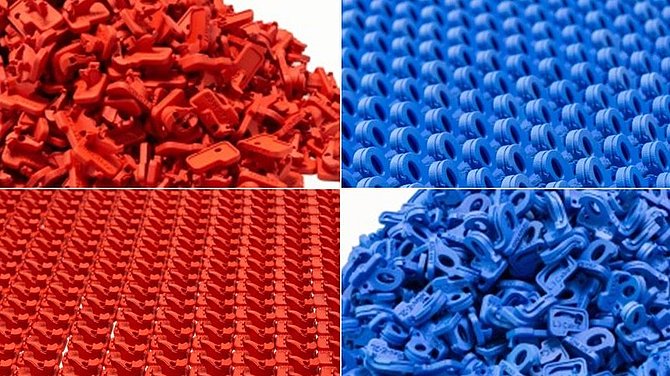

Color infiltration, which allows the material to be dyed in various colors, is suitable for components manufactured using rubber laser sintering or Voxeljet processes.

![[Translate to English:] Selective Laser Sintering (SLS)](/fileadmin/_processed_/e/c/csm_1zu1-Ameise-Header_b3d4651210.jpg)