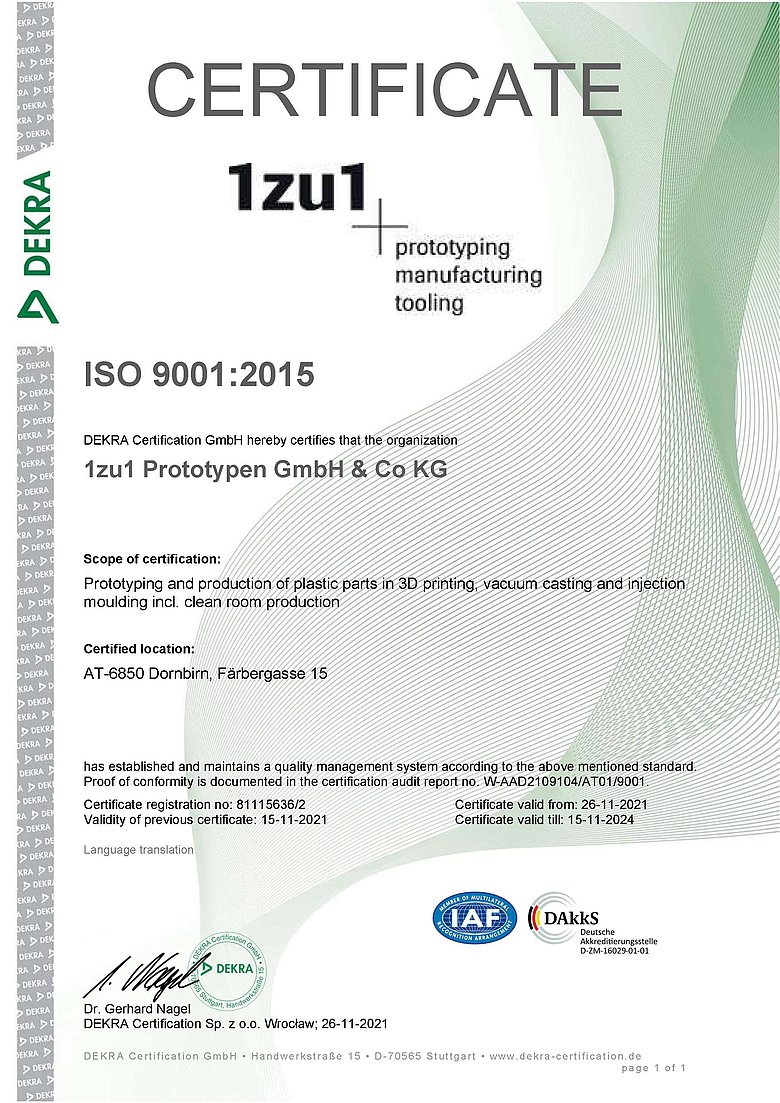

The new ISO 9001:2015 standard.

1zu1 is the first company in Austria to achieve ISO 9001:2015 certification via an audit by DEKRA.

This brings greater transparency to our operational processes, makes improvement potential visible, reduces error rates (and thus costs) and increases product quality for our customers with zero-error tolerance.

Regular audits enable us to meet the increasingly challenging requirements of some of our customers and ensure the quality of our future growth and internationalization.

Our quality standards cover two aspects: technology and processes. Only by combining these two aspects can we ensure reliable and efficient quality management.

Process optimization

1zu1 is the first DEKRA-audited company in Austria to be certified in accordance with the new ISO 9001:2015 standard. This brings greater transparency to our operational processes, flags up where there is room for improvement, reduces error rates and increases product quality, especially for our customers with zero-error tolerance.

8D reports for external errors

Even with perfect processes and the greatest care, errors can happen. Following any customer complaint, therefore, a project team is assembled and all measures documented in an 8D report. Again, all identified improvements are adopted in work processes, work instructions and shop floor papers.

Component testing

Our investment in innovative 3D scanning technology represents a milestone in optical metrology. Perfect quality inspection is guaranteed for every part.

1zu1 metrology offers many practical advantages for quality assurance: accuracy, resolution and measurement-field size are freely definable. The absolute repeat accuracy provides high process reliability with shortened start-up times, accelerated product launches and higher-quality component inspection.