Vacuum-cast PUR special materials Standard-compliant when exposed to heat, fire, food and light

Vacuum casting with silicone molds – a topic that has occupied us at 1zu1 for over 25 years. Vacuum casting is basically suitable as an economical downstream process for reproducing samples in small batches because of the low tooling costs. If you need low-cost plastic prototypes with material properties similar to those of series production at short notice, vacuum casting in silicone molds (silicone molding) is a suitable process.

The master model for vacuum casting is usually produced using the stereolithography process. A master mold made of silicone is cast from this model. This is then filled with liquid polyurethane casting resin (PUR) in the vacuum chamber. The vacuum prevents sink marks and the formation of pores. After curing, the surface finishing takes place.

Our portfolio consists of approx. 70 standard materials. In addition, we offer production of components in special materials.

Available materials

The PUR materials are selected according to the requirements of the series material and the best possible alternatives to these materials are offered. Comparisons are made with numerous series materials. Our enablers have put a lot of effort into analyzing and developing the materials available on the market to meet your requirements.

After thorough testing, we have approved the following special materials for production and prototyping:

- Impact-resistant and bending-resistant polyurethane

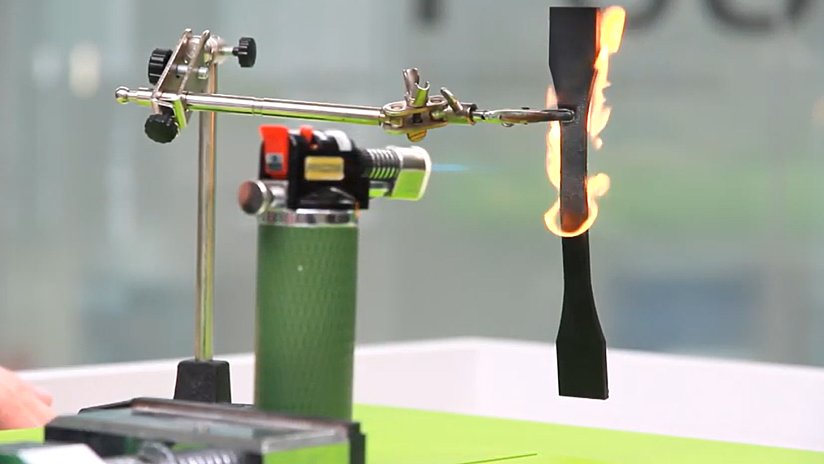

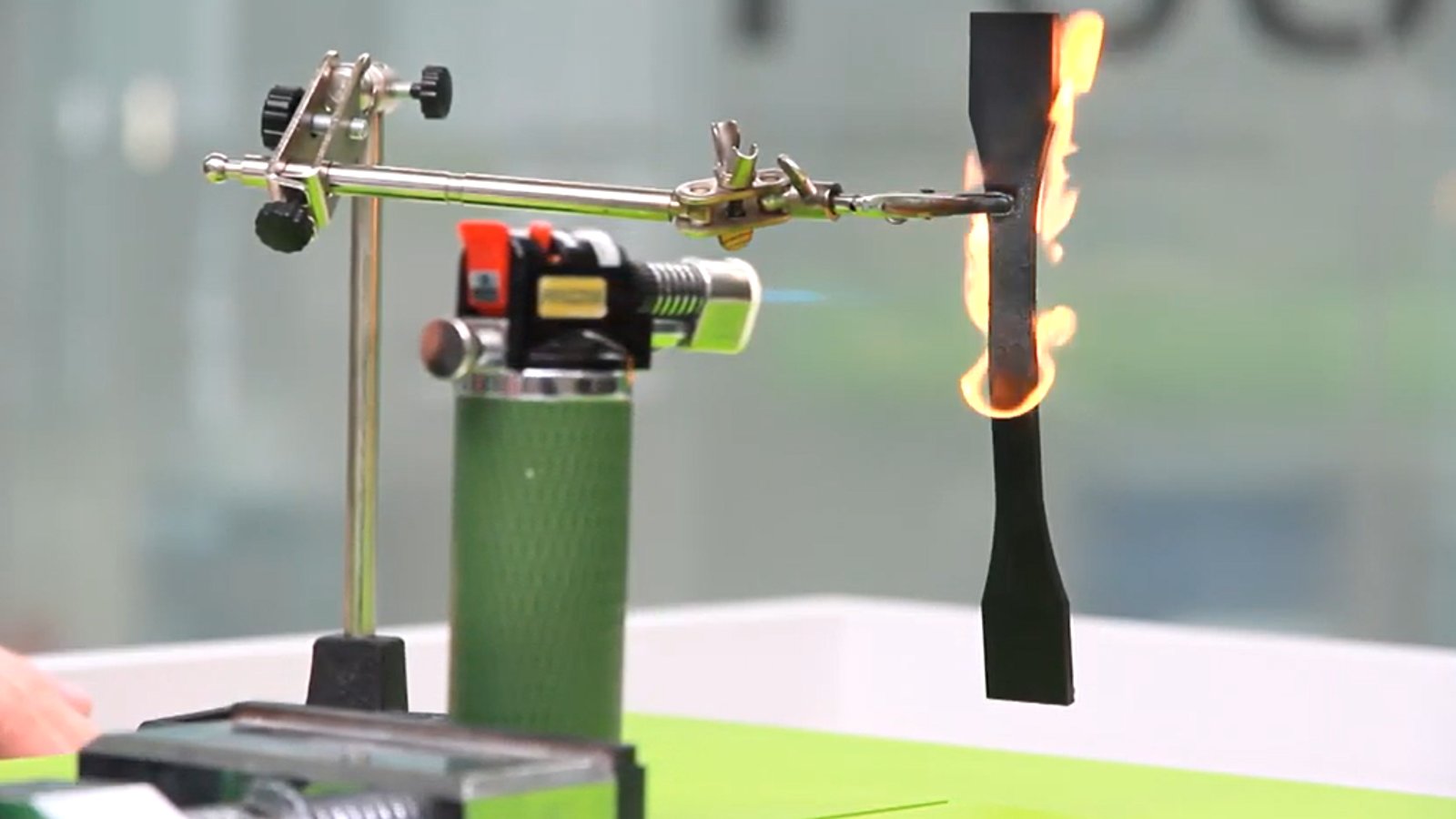

- Flame-retardant and self-extinguishing polyurethane resin

- High-temperature materials up to 190° Celsius

- Diffuser/light-scattering material for improved translucency

| 096 | 098 | 200 | |

|---|---|---|---|

| Shore D hardness | 80 | 86 | 80 |

| Density [g/cm3] | 1.16 | 1.35 | 1.20 ± 0.02 |

| Flexural strength [MPa] | 65 | 133 | 80 |

| Bending modulus of elasticity [MPa] | 1500 | 3700 | 1850 |

| Tensile strength [MPa] | 60 | 55 | 60 ± 2 |

| Notch impact strength [kJ/m2] | 20 | 26 | 41 |

| Elongation at break [%] | 5 | 4 | 13 |

| Heat deflection temperature [°C] | 130 | 90 | 190 |

| Shrinkage [mm/m] | 2 | 2 | 6 |

| Base color | black/brown | cream-colored | light amber |

| colorable | black | black/brown | black/brown |

| Final curing at 23°C | 3 days | 3 days | 3 days |

Special features of the process

When manufacturing parts with special materials, the following must be taken into account. If we offer an output of 1,000 parts from just one silicone mold with standard materials, casting of special materials is not normally possible. The guaranteed output, for example, is 10 to 15 parts when using a thermally stable material, depending on the geometry of your component. Your requirements for the component are the decisive factor here.

Our aim is to meet as many of your requirements as possible with the chosen material. We would be delighted to discuss your needs and advise you about the best solution for your prototype – if at all possible, a “1to1” version of the original.

Your advantages

- Fast, cost-effective production of near-series models (no injection molding tool)

- Surfaces according to customer requirements: high gloss, fine structures, varnishing, printing

- Large material variety

- High accuracy

- Error detection before series

- Possible construction changes or design adaptations can be implemented

Advice tailored to your needs

At 1zu1, we help you find the perfect solution by combining the best technology with a wide range of materials. And this is implemented in the shortest possible time and with the highest technical precision.

Challenge us. What can I do for your project?

Stefan Rädler

1zu1sales

area manager Germany

T +43 5572 33 333-842

stefan.raedler@1zu1.eu

» For perfectly implemented ideas, I propose new technological paths with my customers.«

In motocross and enduro, Stefan Rädler is on difficult paths.

Stefan Rädler

1zu1sales

area manager Germany

T +43 5572 33 333-842

stefan.raedler@1zu1.eu

» For perfectly implemented ideas, I propose new technological paths with my customers.«

In motocross and enduro, Stefan Rädler is on difficult paths.

Klaus Pichler

1zu1sales

area manager Austria

T +43 5572 33 333-838

klaus.pichler@1zu1.eu

»As a cyclist, I know that excellent technology is the key to speed – and therefore to success..«

Klaus Pichler spends his free time in the saddle – he and his road bike conquer Austria’s mountains with endurance and the right pedal stroke.

Sebastian Mathies

1zu1sales

business developer

T +43 5572 33 333-834

sebastian.mathies@1zu1.eu

»1zu1prototyping, that's like fast food on the level of top gastronomy. And if necessary, with a lot of portions.«

Sebastian Mathies knows that the eye also eats. That's why he chooses the right ingredients, the right technology and the necessary finishing steps. The result: prototypes to your taste.

The vacuum process enables fast, efficient and cost-effective production of desired structural and molded parts. In addition, two different materials (hard and soft) can be combined during production. Inserts (magnets, threads, inserts, etc.) can also be integrated into the component.

The production process takes place in a vacuum or under negative pressure. What is the effect of this vacuum? On the one hand, it ensures bubble-free processing of the material. On the other hand, flow resistance within the mold caused by air pockets is avoided. This means that at 1zu1, we can achieve homogeneous, pore-free material properties.

- From master model to casting mold:

- Casting in vacuum

- For simple components directly via a casting mold in 3D printing or milling technology: For series application 1zu1 recommends 100 to 200 pieces.

- 3D printing of silicones:

- Discharging the material via nozzles or injecting a catalyst into a silicone bath

- Cantilevered components are possible

- Layered structure visible

- Vacuum casting materials: use of original silicone, including food-grade silicone

Polyurethane is the collective chemical term for elastic to hard plastics produced from polyalcohols and polyisocyanates. The curing reaction is a polyaddition. Polyurethanes have many uses, e.g. for the production of household sponges, adhesives, paints and floor coatings. Synthetic textile fibers such as polyurethane are also used in the fashion sector.

SHORE hardness, named after Albert Ferdinand Shore, is an indicator used primarily for elastomers and rubber-elastic polymers. It is directly related to the penetration depth and is thus a measure of the material hardness.

Elastomer materials (PU rubber) are available in various degrees of hardness from 30-90 Shore A. Thermoplastic-like materials are available in degrees of hardness from 45-85 Shore D.

| Shore A | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 95 | ||||

| Shore D | 45 | 55 | 60 | 65 | 70 | 80 |

Surface finishes

Here at 1zu1 we can treat master models, duplicated parts and serial parts with special surface techniques according to customer requirements . We finish the prototypes and serial parts via EDM texturing, high gloss, special effects (metallic, silver, partial) or subsequent varnishing.

We can also accommodate individual color samples or color requests (RAL, NCS, Pantone). For this purpose, we offer a wide range of surface treatment processes in manual finishing, depending on the initial technology. Each process can be applied individually, in combination, partially or fully, according to RAL or NCS.

The possibility of individual printing, laser marking as well as hot foil stamping is also available at 1zu1 in-house. Put us to the test!