![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/c/csm_1zu1-MechanischeFertigung-Bauteile1_66b2257535.jpg)

Mechanical manufacturing (CNC) Milling and turning with maximum perfection

Mechanical manufacturing (CNC manufacturing) has a high priority at 1zu1: it is used for the production of prototypes from original materials, for master models and for their post-processing. In addition, CNC manufacturing is important for the business area of plastic injection molding with aluminum molds. Here, aluminum molds are manufactured in short lead times. These are suitable for prototypes and series parts.

In conjunction with the latest generation of robot systems, our turning/milling machines and state-of-the-art 5-axis machining centers increase our capacities and ensure smooth automation.

Metal parts can be manufactured and machined 24/7. 1zu1 is equipped to produce both series and individual parts.

1zu1 know-how

We oversee all phases of your project – from design to finished product. Many years of experience, short communication paths, a flexible approach as well as sound technical knowledge ensure optimum results for mechanical (CNC) prototype production, for the production of workpieces or of assemblies.

Areas of application

- Prototype construction (CNC prototypes) from original materials: complex models and components with our turning, milling and lathe-milling machines within a few days to weeks

- Components that would not be adequate for functional tests if made using other processes

- Transparent parts

- Master models

- Plastic injection molding with aluminum molds

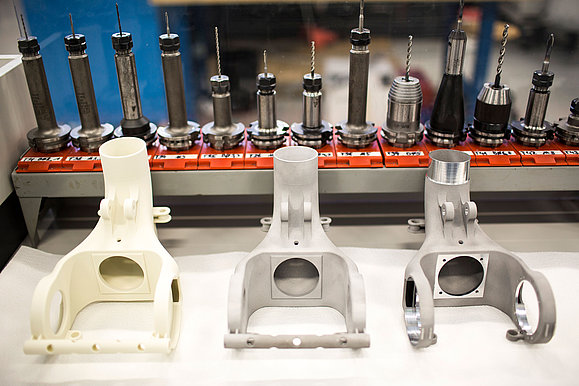

Middle: raw VDD investment casting, right: finished casting

Your advantages

- Suitability for the production of complex models and components from original materials

- Precise results through fully automated production

- Many usable materials

- High surface quality of the produced parts (usability as master model)

- Short throughput times due to high degree of automation

- Inquiry: 1. Configure 2. Upload files 3. Complete your inquiry

- Quote

- Job

- Delivery

Mechanical production in plastic

Mechanical manufacturing in metal

1zu1direkt: Our product range can be ordered online…Advice tailored to your needs

At 1zu1, we help you find the perfect solution by combining the best technology with a wide range of materials. And this is implemented in the shortest possible time and with the highest technical precision.

Challenge us. What can I do for your project?

Michael Eiler

1zu1sales

project manager prototyping

T +43 5572 33 333-891

michael.eiler@1zu1.eu

“Our customers get the best advice and technology for their product.”

Michael Eiler not only keeps the ball in play with his bike, he also successfully brings exciting 1zu1 projects to the finish line. Never solo, always as part of a team!

Michael Eiler

1zu1sales

project manager prototyping

T +43 5572 33 333-891

michael.eiler@1zu1.eu

“Our customers get the best advice and technology for their product.”

Michael Eiler not only keeps the ball in play with his bike, he also successfully brings exciting 1zu1 projects to the finish line. Never solo, always as part of a team!

Klaus Pichler

1zu1sales

area manager Austria

T +43 5572 33 333-838

klaus.pichler@1zu1.eu

»As a cyclist, I know that excellent technology is the key to speed – and therefore to success..«

Klaus Pichler spends his free time in the saddle – he and his road bike conquer Austria’s mountains with endurance and the right pedal stroke.

Armin Huber

1zu1sales

area manager CH / LI / Vlbg

T +43 5572 33 333-868

armin.huber@1zu1.eu

“At 1zu1, rapid prototyping means being really fast, even faster, the fastest to find solutions that work. But we take our time on the consulting side.”

Armin Huber enjoys roaring through the Alps on his motorcycle. Just like at 1zu1, it’s a hobby in which speed and technology must come together.

These are PARASOLID, DXF and STEP.

Parasolid is a modeling kernel for 3D CAD systems, originally developed by the company UGS and acquired by Siemens PLM Software in 2007.

The STEP exchange format (Standard for the Exchange of Product model data) is a standard for describing product data. It enables the exchange of three-dimensional graphics and product definitions in heterogeneous computer-aided CAD, CAM and CAE systems.

A DXF file (Drawing Interchange File Format) is a file format for data exchange in CAD. This file format DXF file is integrated into the CAD program AutoCAD. This enables and performs data exchange between different types of AutoCAD executions.

Surface finishes

Here at 1zu1 we can treat master models, duplicated parts and serial parts with special painting techniques according to customer requirements. We finish the prototypes and serial parts via EDM texturing, high gloss, special effects (metallic, silver, partial) or subsequent varnishing. We can also accommodate individual color samples or color requests (RAL, NCS, Pantone).

For this purpose, we offer a wide range of surface treatment processes in manual finishing, depending on the initial technology. Each process can be applied individually, in combination, partially or fully, according to RAL or NCS.

Systems

The production of the injection molded parts is carried out exclusively with the aluminum molds manufactured by us. These are manufactured using high-quality, reliable processes that meet the highest demands for precision of plastic parts, shape, material and surface structures. When the injection-molding machine is in a vertical position, we can insert a wide variety of parts into the mold and overmold them. The advantages are as follows: We can overmold cables. Make plug parts with insert pins. Injection-mold multi-component parts.

| CNC milling technology | Type | Characteristic value [mm] | Maximum spindle speed |

|---|---|---|---|

| DMG 5-axis HSC (2 pcs.) | HSC 55 linear + Erowa palletizing | X 450 Y 580 Z 460 | 28,000 rpm |

| DMG 5-axis HSC | HSC 30 linear + Erowa palletizing | X 320 Y 300 Z 280 | 40,000 rpm |

| DMG 5-axis (2 pcs.) | DMU 50 eVo linear | X 500 Y 450 Z 400 | 24,000 rpm |

| DMG 5-axis | ecoMill 70 | X 750 Y 600 Z 520 | 12,000 rpm |

| DMG 5-axis | DMU 70 | X 750 Y 600 Z 520 | 14,000 rpm |

| DMG 3-axis | DMC 1035 V ecoline | X 1035 Y 560 Z 510 | 12,000 rpm |

|

Turning/milling technology |

Type |

Characteristic value [mm] |

More information |

| DMG Revolver Turning/milling | alpha 300 | max. diameter/length 200/335 Passage Ø 51 Y-axis ±40 | 12-way Revolver 6000 rpm |

| MAZAK Revolver Turning/milling | 200 MY L | max. diameter/length 210/500 Passage Ø 65 | 12-way Revolver 6000 rpm |