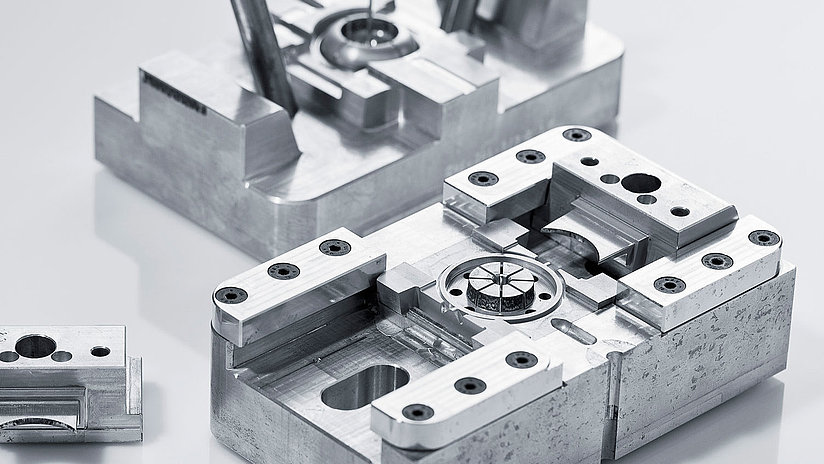

The production of the injection molded parts is carried out exclusively with the aluminum molds manufactured by us. These are manufactured using high-quality, reliable processes that meet the highest demands for precision of plastic parts, shape, material and surface structures.

Our Boy, Arburg, Demag and Sumitomo Demag injection-molding machines generate clamping forces ranging from 10 to 160 metric tons.

When the injection-molding machine is in a vertical position, we can insert a wide variety of parts into the mold and overmold them.

The advantages:

- We can overmold cables.

- Make plug parts with insert pins.

- Injection-mold multi-component parts.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/d/csm_1zu1-Spritzguss-Reinraum2_eaf7711bca.jpg)