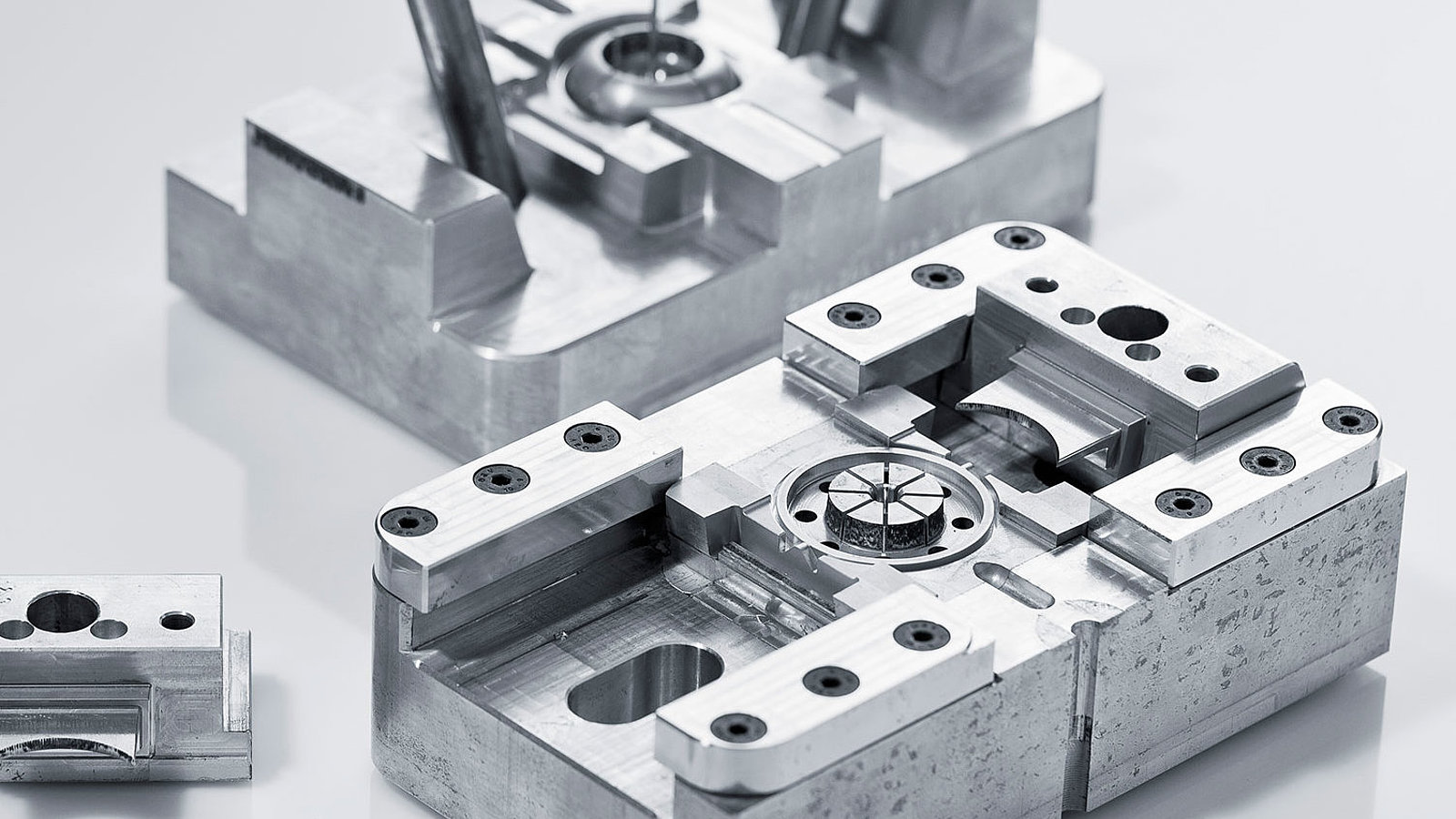

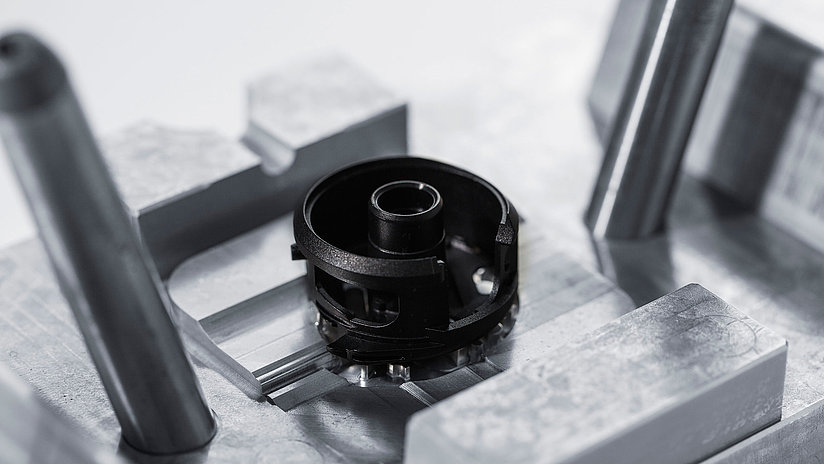

High Speed Cutting – HSC: This process is used at 1zu1 to produce mainly aluminum tools and mold inserts for the production of small series in original materials. State-of-the-art 5-axis milling technology guarantees maximum precision for our mold inserts. This enables us at 1zu1 to offer high-precision components from the injection molds. The tool-mold inserts are machined using state-of-the-art machine tools. The optimal article size is 250 x 150 x 100 mm. Do you need larger dimensions? Please contact us, many things are possible.

Tool production Injection-molding tools with the shortest lead times

Your advantages

- Injection molded parts produced with the material used by the customer as a series material

- Extensive conformity of injection molding conditions with those of series molds

- Fast turnaround times from 2 weeks

- Several runs of 1,000 units possible

- Technical accuracy

- Rapid response to requests: Our short lead times and ability to think and work in small quantities enable us to provide solutions that series manufacturers typically do not want to – or cannot – offer.

- Uncomplicated and fast change management

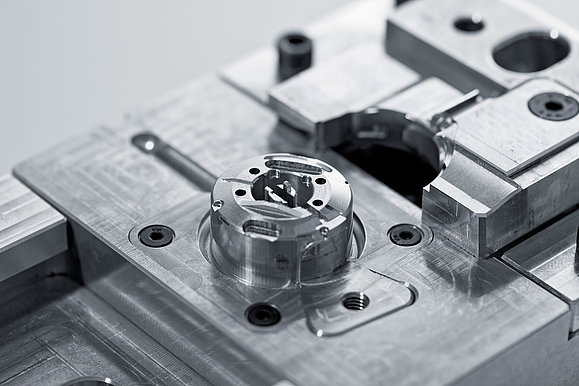

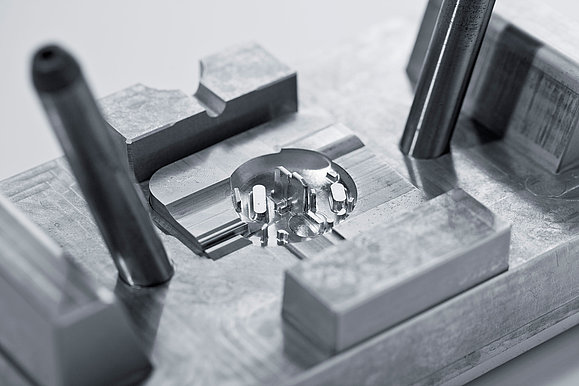

The sprue gate is the simplest form of sprue. It offers the lowest flow resistance and is therefore mostly used for cavities that are difficult to fill. Disadvantage of the sprue gate: It usually has to be removed mechanically after demolding, and the sprue marking may remain visible.

In tunnel gating, the injection molded part is gated from the side. It is then separated from the sprue when the mold halves are opened or ejected. The advantage of this is that there is automatic separation from the molded part. The disadvantage: high pressure loss.

A hot runner or hot runner system is a type of sprue system used in the processing of plastics, particularly in the mechanical injection molding of thermoplastics. It is thermally insulated from the rest of the injection mold and has a higher temperature.

The film gate is used for large-area parts. The wide flow front ensures optimum quality. The material flows uniformly into the cavity in one direction, thus preventing internal stresses and distortion in the injection molded part.

A pinpoint gate is a small gate with a small diameter in an injection mold. It leaves only a small, point-shaped gate on the compact injection molded part and can be easily removed by breaking it off.

Aluminum or steel?

Normally, mold inserts are made from high-strength aluminum.

The advantages:

- Aluminum molds for plastic injection molding are more cost-effective. The cost savings compared to single-series injection molds made of steel are 40 to 70 percent (European comparison).

- Exact mold geometry as well as fast availability: At 1zu1, we resort to steel inserts if the desired output quantity or the selected plastic prevents the use of aluminum.

- The injection molded parts are delivered: The forming parts remain at 1zu1 and are reinstalled into the master molds available in-house if further requirements arise.

- Mold service life up to 50,000 pieces with 1 cavity possible (plastic without filler)

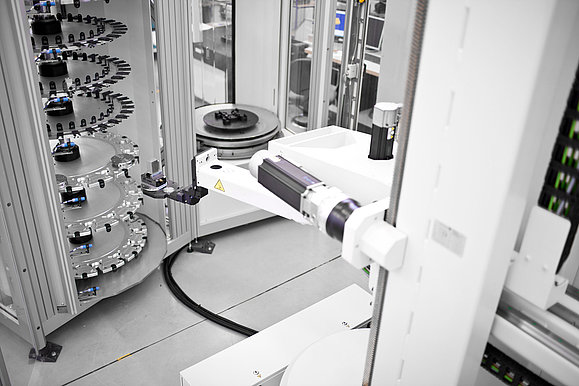

- Multi-component injection molding via part transfer

- Sprue, tunnel or hot-runner gate

- Injection molding parts production in cleanroom possible

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/d/csm_1zu1-Spritzguss-Reinraum2_eaf7711bca.jpg)