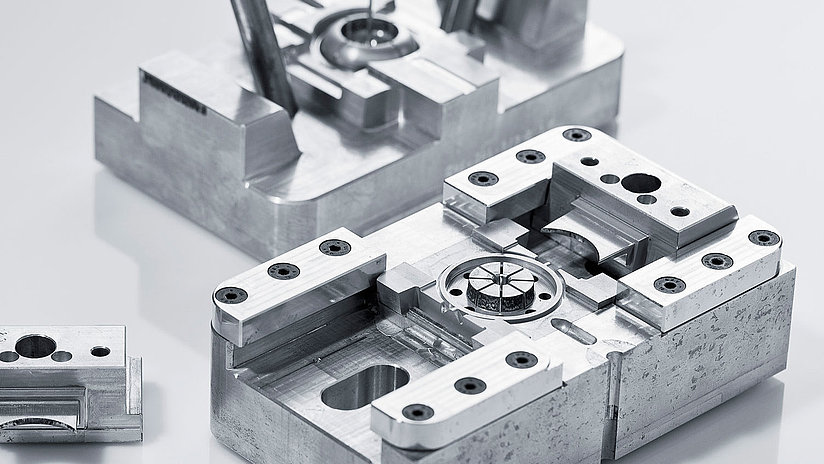

We use your exact desired material. Using the classic injection molding process, the plastics are injected into injection molds. To live up to our philosophy of being a rapid service provider, we manufacture the injection mold inserts required for the production of the plastic parts from aluminum. The technology used: HSC in our tool shop .

Fast processing

Often only hours pass between an order and the start in the tool shop. This makes it possible to be on the injection molding machine with the mold and produce plastic parts with original materials in time windows of 2 to 3 weeks.

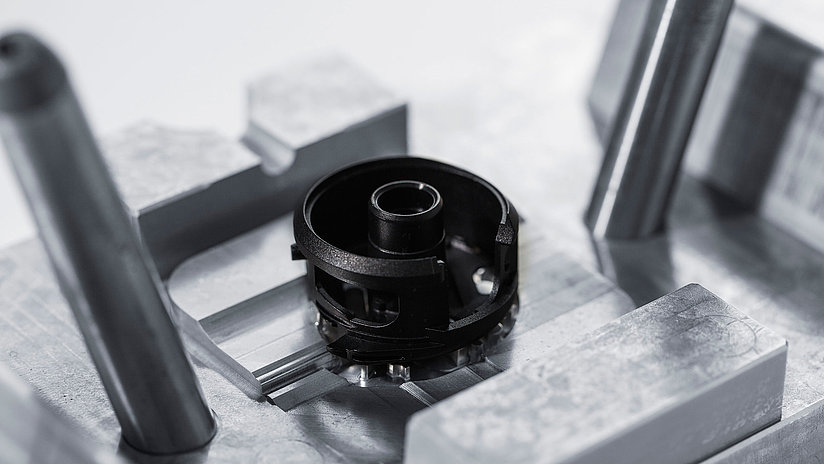

In this way, we produce prototypes in the original material as well as series parts in batches of up to 50,000 units or more. And that within a very short time. Our injection molding machines have clamping forces from 10 to 160 metric tons. We manufacture your injection molded parts with our aluminum molds. This high-quality, reliable process allows an almost infinite choice of shapes and surface textures.

The great strength of 1zu1 is to produce complex components in dimensions of up to DIN A5 projected area. And also with inserts, pins and cables. The fields of application are medical and laboratory equipment, devices, machines, power tools and industrial products of all kinds.

1zu1 is also well equipped for the area of very small components. Today, our milling technology allows corner radii of 0.3 mm. This gives corners on the component almost sharp edges. With 2 BOY injection molding machines with 10 metric tons clamping force, 1zu1 is also very well equipped for the injection molding of small components from approx. 0.5 cm³ part weight.

We produce the following variants, among others: Multicomponent injection molding by part rearrangement, sprue, tunnel or hot runner molding or complex parts with inserts up to approx. A5 projected area.

We ensure their quality by using various measurement techniques such as 3D scan or computed tomography. Starting in 2022, at least one manufactured component will be scanned with a newly acquired CT device after each production process and the manufacturing tolerances will subsequently be evaluated.

Surface finishes

Here at 1zu1 we can treat master models, duplicated parts and serial parts with special surface techniques according to customer requirements . We finish the prototypes and serial parts via EDM texturing, high gloss, special effects (metallic, silver, partial) or subsequent varnishing.

We can also accommodate individual color samples or color requests (RAL, NCS, Pantone). For this purpose, we offer a wide range of surface treatment processes in manual finishing, depending on the initial technology. Each process can be applied individually, in combination, partially or fully, according to RAL or NCS.

The possibility of individual printing, laser marking as well as hot foil stamping is also available at 1zu1 in-house. Put us to the test!

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/d/csm_1zu1-Spritzguss-Reinraum2_eaf7711bca.jpg)