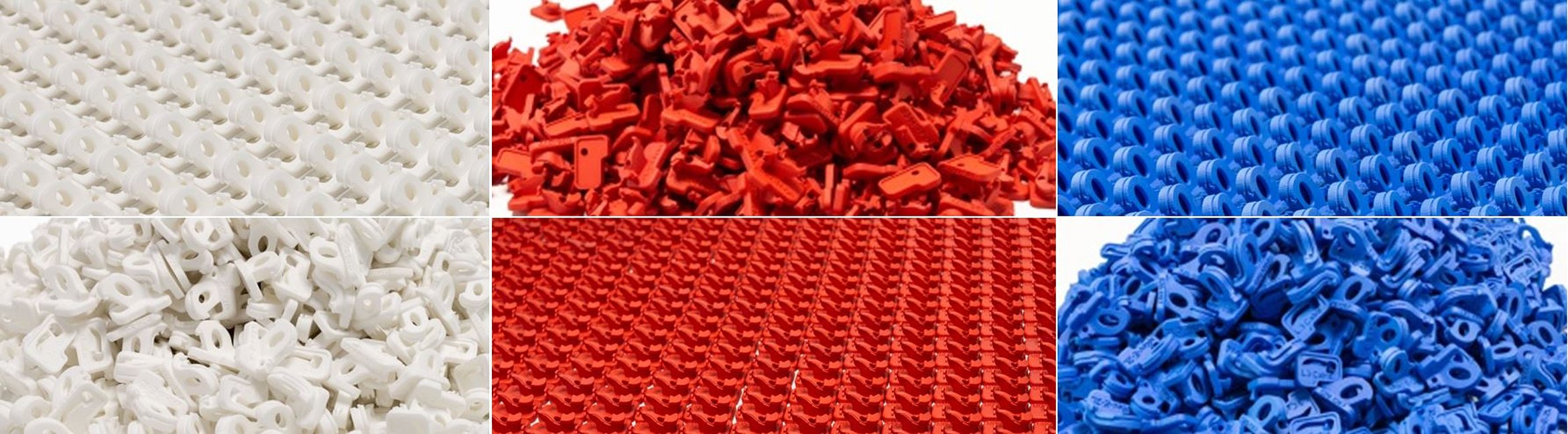

Because the eye always plays a part in our decisions, color is a key success factor in product design. Previously, the „only“ way of coloring our laser-sintered parts was to paint them. Now, a new coloring system for additively produced models has opened up new and unprecedented possibilities. Finishing and dyeing in the desired color, from the raw part to the finished product.

Color 3D-printed parts

Painting is good, but heatset impregnation in the desired color is even better. The application of paint can cause dimensional changes, so that threads may no longer function properly, for example. The new coloring system from DyeMansion overcomes these limitations: the polyamide parts are dyed under pressure and at high temperatures. Depending on their size, several hundred parts can fit inside the dyeing machine at once. The processing times for 3D printing remain virtually unchanged. In the first three months alone, we have dyed 40,000 units on this system.

Color brilliance

According to Markus Schrittwieser, Head of Additive Manufacturing: „Our customers are delighted. Laser sintering parts just the right quality of color. We can achieve large quantities, short throughput times and hitherto unpaintable geometries.“

The new process also offers functional advantages: the color application is no longer measurable, so that elements such as catches or threads can be produced with greater precision and the parts are protected against scratches.

As a positive side effect, the surface becomes silky matt. Both the appearance and haptics are improved and even closer to the original.

Surface design

„The more often additive processes are used in manufacturing, the more important it becomes to ensure a first-class finish“, says 1zu1 company founder Hannes Hämmerle. In addition to heatset impregnation, we also offer other in-house finishing techniques: pad and digital printing, hot-foil stamping, laser engraving and laser cutting.

Refining and finishing

We know that function and design are inseparably linked. That's why new production methods are systematically coupled with new surface finishing methods. Why not judge our look & feel expertise for yourself? Your 1zu1 consultant will be happy to show you the whole range of options in glorious technicolor!

![[Translate to English:] Lasersintern: Lackieren ist gut, einfärben ist besser. [Translate to English:] Lasersintern: Lackieren ist gut, einfärben ist besser.](/fileadmin/_processed_/3/9/csm_Foto_12.04.18__08_36_24_6f9ae69ce8.jpg)