Sandblasted surfaces wanted? No!

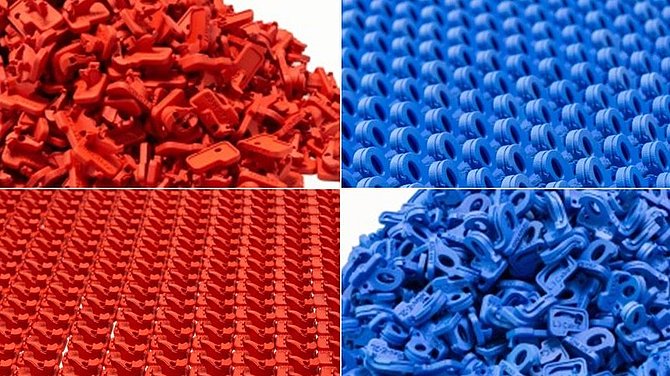

In addition to the chemical smoothing process, at 1zu1 we offer the option of compaction blasting so that the outer surfaces are clean and smooth thanks to the blasting with plastic beads. The process is carried out in-house at 1zu1 using the new Powershot DUAL Performance from DyeMansion. Compaction blasting is the preliminary stage of hot pressure impregnation and ensures a stain-free and colorfast surface during the subsequent dyeing process.

The process achieves the best effect on larger surfaces. This applies to robust parts made of PA2200 or PA3200 GF up to an edge length of 200 mm. For very delicate parts, we recommend the chemical smoothing process, which we also offer in-house. The specialists at 1zu1 will be happy to help you and find the right solution for you.

Your advantages

- In-house technology - we work with you to select the best process for improving your SLS series parts.

- Compaction blasting or chemical smoothing? - Both processes have their justification. Discuss your application with us.

- Both technologies ensure stain-free coloration of plastic surfaces.

- There is hardly any delay in delivery, as all technologies are available just in time.

- No subsequent staining of plastic components.

- No gray plastic parts, as irradiation is carried out with plastic balls.

![[Translate to English:] Selective Laser Sintering (SLS)](/fileadmin/_processed_/e/c/csm_1zu1-Ameise-Header_b3d4651210.jpg)