Milling, turning, 3D printing, polishing, painting, engraving: For the new collection of Swarovski ballpoint pens, 1zu1 Prototypes were able to perfectly combine the company's wide range of production technologies. Only by doing so could 200 different parts be produced within four weeks – and in the highest quality.

When project consultant Reinhard Raffl personally handed over the ballpoint pen mockups on the day of delivery, Swarovski was astounded: „We had never seen prototypes of this quality before,“ says project manager Martina Stattelmann. The head of the „Writing Instruments“ product category at Swarovski, Lothar Maier, only wants to produce prototypes in Europe from now on: „This way we can provide our production partners in Asia with perfect models.“

Mr. Maier, Swarovski is best known for its jewelry and figurines. When did your company also begin offering writing instruments?

Lothar Maier: During the 2009 financial crisis, we thought about how we could address new customer groups. One idea was to add writing instruments that perfectly embody the brand's DNA to our product range – i.e. with sparkling crystal.

Within three months, we had developed the first models. After an extremely positive market test, the decision was made in favor of series production. The concept then proved itself on the market – within the first few months we sold half a million units. Writing instruments are now one of the six major product categories at Swarovski.

Martina Stattelmann: Swarovski is a very feminine brand and has positioned its writing instruments as accessories, unlike most other stationery manufacturers. We can therefore offer a product that is unique on the market and very popular as a gift. While jewelry is very personal, you can gift a pen to someone you don't know all that well.

How is a new collection of writing instruments created?

Lothar Maier: We are currently fundamentally revising this process. We implemented our first series of pens very spontaneously. We are now developing the processes to include professional management of the product cycle.

Previously, we worked closely with our suppliers in Asia on product development. We would send them drawings and renderings and ask them to show us their solutions. But there is obviously a different perception of the design process over there. This often resulted in delays and numerous iterations. And, in the end, we didn't really get what we wanted.

I then talked to colleagues in other industries who have the same problem. As a result, prototyping has become an important topic for us. It enables us to provide our partners in Asia with perfect models – and then really get what we want.

How did you become aware of 1zu1 Prototypes?

Lothar Maier: Our product development department in Wattens had worked with 1zu1 Prototypes before. I went to Dornbirn at the beginning of this year and took a look at the company and all their technology. The possibilities I saw there impressed me a great deal.

Reinhard Raffl: At that time, we first discussed the project in rough terms and looked at how we could best structure a partnership. We were asked to produce mock-ups for market research – i.e. non-functional models that look like the subsequent series product. At that time there was talk of three pens per design and I quoted three weeks as the lead time, including surface finish and painting. That was rather tight, to say the least.

But it didn't stop there ...

Lothar Maier: In parallel to our discussions with 1zu1 Prototypes, we created six designs via our design studio in Paris and external designers in Spain and Italy. In the end, we had seven of each of them produced in order to test the designs with consumers. Ultimately, we wanted to make an informed decision on this basis and send visually finished prototypes to Asia as a briefing for production.

This was where we really saw the strengths of 1zu1 Prototypes. Once the quotation was received and the order placed, everything went like clockwork. We agreed on a schedule and, even though we increased the number of units once again, it was adhered to 1,000 percent.

How did the project proceed internally at 1zu1 Prototypes?

Reinhard Raffl: For us, the collaboration was very pleasant. The customer told us how the product should look. Also the weight needed to correspond to that of a ballpoint pen. The choice of which processes to use for this, however, was left up to us. This allowed us to contribute our full range of expertise. We were also able to define the details of the design ourselves, for example whether we screwed or glued the parts together.

Due to the tight schedule, we then agreed that the design data would be delivered in stages. We received the first design in early May, the last one more than a week later. However, this allowed us to immediately start transferring and processing the data, and making the necessary design adjustments.

At that time, were there still any open issues to be clarified?

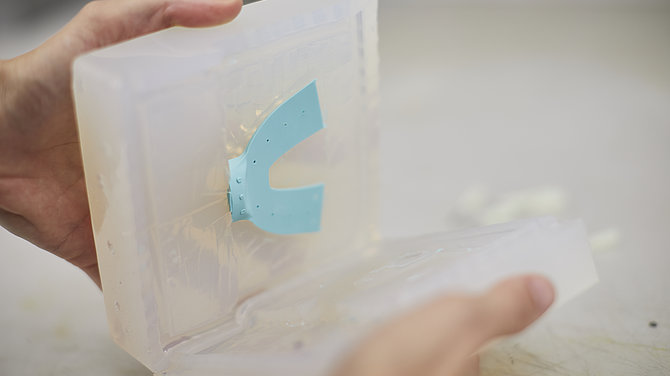

Reinhard Raffl: Just two days after we received the first batch of data, I went to Swarovski in Männedorf to inspect the surfaces. For example, there were parts that would later be chrome-plated in series production. As this was not possible for the prototypes in the short time available, we suggested polished aluminum as the surface. This is very similar in terms of appearance.

We had produced an acceptance sample on which the colors and surfaces were visible. We immediately received approval for this and were able to start production.

Were there any particular challenges during the project?

Reinhard Raffl (laughs): The only real headache was the application of the crystals. Gluing them on or filling them in the transparent cavities was a major hassle.

Apart from that, the main challenge in this project was executing the multitude of production steps in a short time frame. In total we had to produce over 200 parts. We had highly complex turned parts that were both conical and oval. We had vacuum-cast parts that needed a perfect high-gloss surface to create transparency. We also had to have the company name laser engraved. Other parts had to be painted. For one part, the recesses for the crystals had to be milled.

At this stage, we really benefited from the fact that we can do practically everything ourselves in-house, and can thus control all the various processes.

June 1 was agreed as the delivery date. Be honest, how tight did things get in production?

Reinhard Raffl: There was no question that we would keep to the schedule. Nevertheless, we worked until the last minute. But that was mainly due to our own quality standards. We want to deliver a perfect product and so are always finding little things that we want to improve – often things the customer might not even notice. This perfectionism is certainly one of our strengths.

On June 1 we packed the 42 finished pens in the cases that we had made especially for delivery to the customer. At 11 am, I personally delivered the pens to Ms. Stattelmann in Wattens. At 2 pm, the mock-ups were dispatched all over the world for the market tests.

Ms. Stattelmann, how satisfied were you with the mock-ups you received from 1zu1 Prototypes?

Martina Stattelmann: Quite honestly – we had never seen prototypes of this quality before. Furthermore, our work with 1zu1 was characterized by adherence to delivery dates, reliable deliveries and a very pleasant collaboration. I would award them five stars.

Lothar Maier: If you want to conduct serious market tests, you also have to present the consumer with prototypes that come very close to the finished product. This is the only way to achieve a meaningful result. We have therefore decided to continue working on this basis for new products in the future.

Final question: What did the market research reveal?

Lothar Maier: We interviewed consumers in Chicago, London and Shanghai. The results were very positive. One design is already being implemented and will be brought to market next year. Two other models are still in development and will be added to our range at a later date.

Many thanks for the interview!

Interviewed:

Lothar Maier is head of the Writing Instruments product category at Swarovski in Männedorf near Zurich. Martina Stattelmann is responsible for product innovations in Swarovski's writing instruments. In addition, as project manager she is the central point of contact during all phases – from the first design sketches to production and marketing and all the way through to the end of the product's life cycle. Reinhard Raffl was a key account customer consultant at 1zu1 Prototypes.

The interview was conducted by Wolfgang Pendl. Photos by Darko Todorovic.

![[Translate to English:] Mechanical manufacturing (CNC)](/fileadmin/_processed_/3/c/csm_1zu1-MechanischeFertigung-Bauteile1_1b16c9709a.jpg)