From initial design to production-ready product in just two and a half months: all made possible by 3D printing. Munich-based start-up Sentrity is launching a pocket-sized distance meter. It projects the minimum distance for social distancing on the ground and can be used for other purposes even after the pandemic. 1zu1 was delighted to be asked to contribute the housing for the prototype and also made a few practical suggestions.

Keeping your distance from other people is not easy. It is easy to overlook markings on the ground or miss warning signs. And yet, during the coronavirus pandemic, a little distance from one's fellow human beings is and remains one of the most effective means of minimizing the risk of infection.

Thomas Klotz has been developing hardware and software products with his company Klotz Communications for many years. Together with marketing and sales expert Till Kaestner, he decided he would try and invent a distance measuring device that is suitable for everyday use and also inexpensive. Now the two are launching the Sentry, a product that potentially has a wide range of different applications.

The Dornbirn-based high-tech company 1zu1 was involved from the initial design to the functional prototype. This was manufactured using the selective laser sintering (SLS) process. It took just two and a half months from the design to the production-ready product.

We talked to Till Kaestner and Stefan Rädler, Sales Manager for Germany at 1zu1, about the project.

Mr. Kaestner, could you briefly explain what Sentry is all about?

Till Kaestner: This was an idea I developed together with my business partner Thomas Klotz, a pioneer in the audio and broadcasting industry, at the beginning of the coronavirus pandemic. It is a portable device for distance measurement. With the Sentry, a laser projects a line onto the ground at the defined minimum distance. An optical sensor continuously measures the distance of people in the vicinity. If someone steps inside the minimum distance, the device starts flashing. This in turn causes a change in behavior. Because visual and dynamic signals that react to me and my movements generate a much higher level of attention than warning signs, whose effect wears off over time. The Sentry enables privacy and health protection – and does so easily and cost-effectively.

Will such a product still be needed after the pandemic?

Till Kaestner: We quickly noticed that the issues of privacy and maintaining a distance from other people are important regardless of the pandemic. This is necessary, for example, in banks, in the pharmacy or in the hotel, where it is important to maintain discretion. Or even when you're waiting in a queue, so that you don't feel other people breathing on the back of your neck or have to put up with unpleasant smells at close range. This is all about the need for personal space. What's more, there will be flu outbreaks again in the future, and that's when Sentry will be useful for high-risk groups.

How did you hear about 1zu1?

Till Kaestner: We decided to go for rapid prototyping very early on so that we could map the ongoing development steps quickly and learn as we progressed. As we are launching a completely new product category with Sentry, it was also important for us as founders and developers to hold the device in our hands, to feel it, to experience it. Because a distance meter like this naturally also has a high emotional impact. So we needed prototypes that we could use quickly and test for their suitability. With 1zu1 we found an experienced and competent partner who supported us with their expertise during the development phase.

How was the decision made for the manufacturing process of the housing parts?

Stefan Rädler: In the pandemic, every day counts. The decisive factor in product development was therefore time-to-market, where 3D printing is really the only option. This means that ongoing adjustments can be tested quickly during development. Customers only have to wait three or four days after a change and then they have the modified part in their hands.

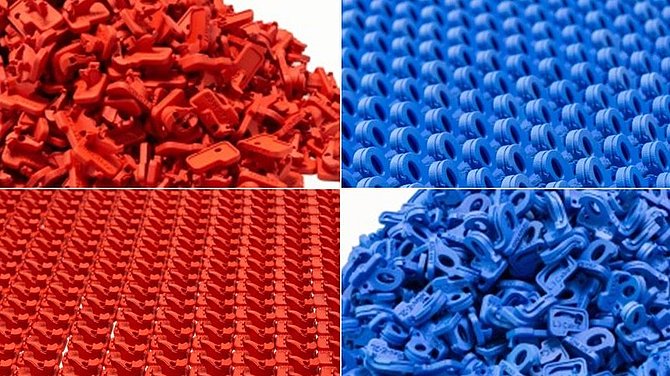

We chose selective laser sintering (SLS) because it gives you high quality at a low cost. This was the perfect option during the development phase. If, as in the case of the Sentry, it is planned to produce large series of more than 5,000 units subsequently, it is worth producing injection-molding tools.

What part did 1zu1 play in this?

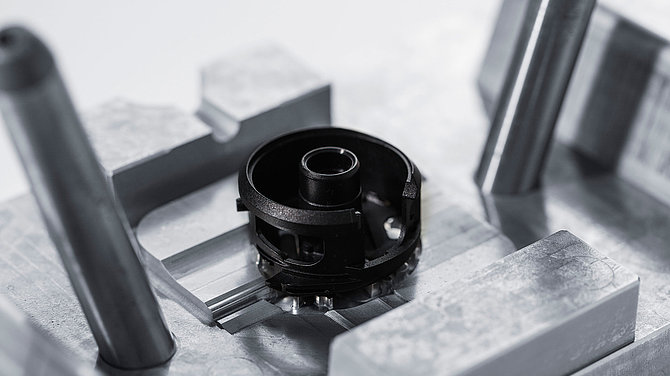

Stefan Rädler: We received a request with 3D data in late summer and immediately found the project exciting. After the initial consultation, we produced the SLS parts for the first prototype, which was already functional. We chemically smoothed them and dyed them black. So they were visually hardly distinguishable from the later series parts. I then personally delivered the parts to Munich and we assembled them together with the customer on site. This was ideal as we could then discuss possible improvements and further development right away. My experience is that if you know each other personally, it makes it that much easier to work together.

In the following weeks, we not only implemented minor changes in the design, but also produced additional small parts. For example, within a few days we were able to produce a flexible protective cover with SLS rubber that was also colored black. At the end of November, after several iteration steps and numerous optimizations, we were already able to hand over 30 production-ready prototypes. That was the prelude to the next step, the search for investors. In series production, the parts are then injection molded.

Time was a decisive factor. Were there any other challenges?

Till Kaestner: There are always some in a development process like this. For example, we tinkered with how to wear the device comfortably in everyday life for quite some time. First we tried it with a lanyard around the neck. In the practical test, it became clear that wouldn't work. We then worked together with 1zu1 and developed a clip solution. We also revised the signaling several times as time went on. Thus, different modes were created, ranging from proactive (constant projection) to reactive (projection only when the minimum distance is exceeded).

What are the next steps for Sentry?

Till Kaestner: We are convinced that our product has a long-term justification and that there are a number of applications for it. During the pandemic, the Sentry can be part of security concepts at events, in the catering industry and in tourism. Used as a stationary device, it is also suitable as an instrument for intelligent visitor guidance and entry management at events or in museums, as well as for setting up security and discretion zones. This is a product which can be used to dynamically control queues in the future. We are currently looking for pilot customers from the business and public sectors.

How did the collaboration with 1zu1 go?

Till Kaestner: The collaboration with 1zu1 was flawless from the first inquiry to the delivery of the final prototypes. We have therefore taken advantage of 1zu1's services frequently over the past few months and have always been able to rely on the quality and service. We have been lucky to find a partner with an understanding of our needs who also suggests helpful solutions.

Stefan Rädler: It is precisely this personal contact, advice and service that make the difference for me. In this way, we can show what 3D printing can do. It is still often said that 3D printed parts are of poor quality. But that's really not true. Our parts are fully operational in products, both visually and functionally.

In conversation: Till Kaestner is founder and CEO of the Munich-based start-up Sentrity. Stefan Rädler is responsible for sales in Germany at 1zu1 in Dornbirn. The interview was conducted by Joshua Köb, photos by Darko Todorovic.

![[Translate to English:] Selective Laser Sintering (SLS)](/fileadmin/_processed_/e/c/csm_1zu1-Ameise-Header_b3d4651210.jpg)