Components used to be checked for quality using optical measurement techniques. But this prevented the capture of complex, internal geometries and required pre- and post-treatment steps for transparent or reflective parts. This type of measurement was limited in its accuracy.

Complete digital recording

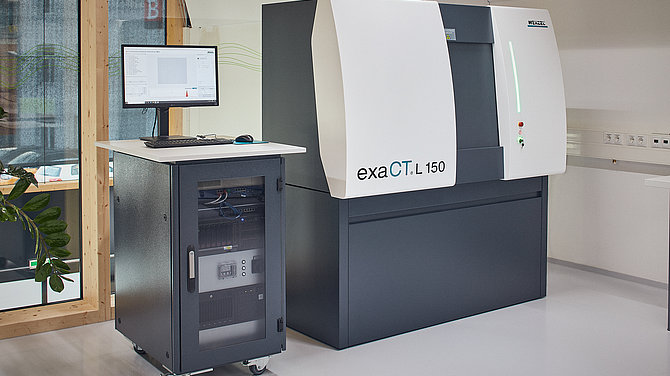

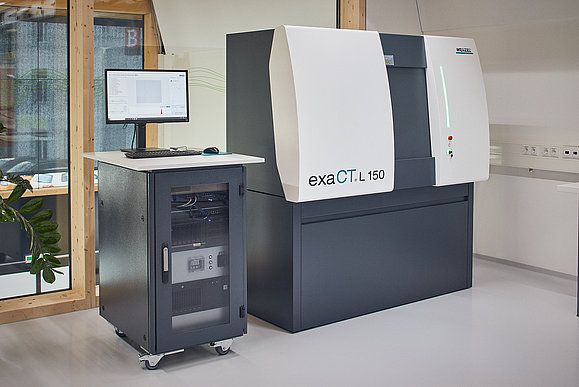

The innovative 3D measurement made possible with the new computed tomography machine allows 1zu1 to make a complete digital scan of all internal and external structures of the components for the first time, without touching or destroying the part. The machine allows absolute quality certification for delicate and complex injection molded and 3D printed parts with an accuracy of five thousandths of a millimeter (0.005 mm = 5 μm) over the entire component surface and a very high resolution. Depending on the object, the measurement process takes between ten and 20 minutes.

You receive a detailed measurement report for each batch, save yourself further measurements and thus benefit from a rapid and seamless development process from prototype to series product.

Pioneering work for industrial measurement technology

The new CT technology allows previously impossible insights into the interior of the components – and almost in 4K resolution. A milestone in prototype and small series production! Why not explore the capabilities of the system with us?

Your advantages

- Full, high-resolution (3000 x 2500 pixels) 3D image of the object

- Problem-free measurement of transparent and reflective parts

- Measurement of micro parts and components with a size of up to 150 x 300 millimeters

- Inspection of dimensional accuracy, material inclusions, impurities, material distortion and shrinkage

- Customer-friendly presentation of the evaluation

- Process monitoring thanks to quality proof for each batch

- Assembly analyses possible through multimeasurements of up to 20 parts

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/e/csm_20211103_DAT_0035_a5a27338ed.jpg)