New opportunities with AM

Unlimited possibilities from a batch size of one

The Spiral Lamp

Whenever objects need to be created from data, Selective Laser Sintering (SLS) is in demand. It allows rapid production of detailed functional prototypes or small series from batch sizes of a single piece. Additive manufacturing with SLS is a superb option for product design thanks to the unlimited possibilities and design freedom. Components are produced very fine, slightly roughly sanded surfaces and ultra-thin layers with a thickness of just 0.1 mm. In terms of the desired materials, PA, glass-reinforced PA, PP and rubber are available.

The Spiral Lamp was similarly designed as a two-dimensional surface, printed and then shaped to give it volume. The designers learned to think cost-effectively – by optimizing the AM process it was possible to simultaneously manufacture over 100 lamps in a single job, while also significantly reducing the component costs to approx. 40 EUR/lamp by making optimum use of the construction space.

Fast, flexible, cost-effective

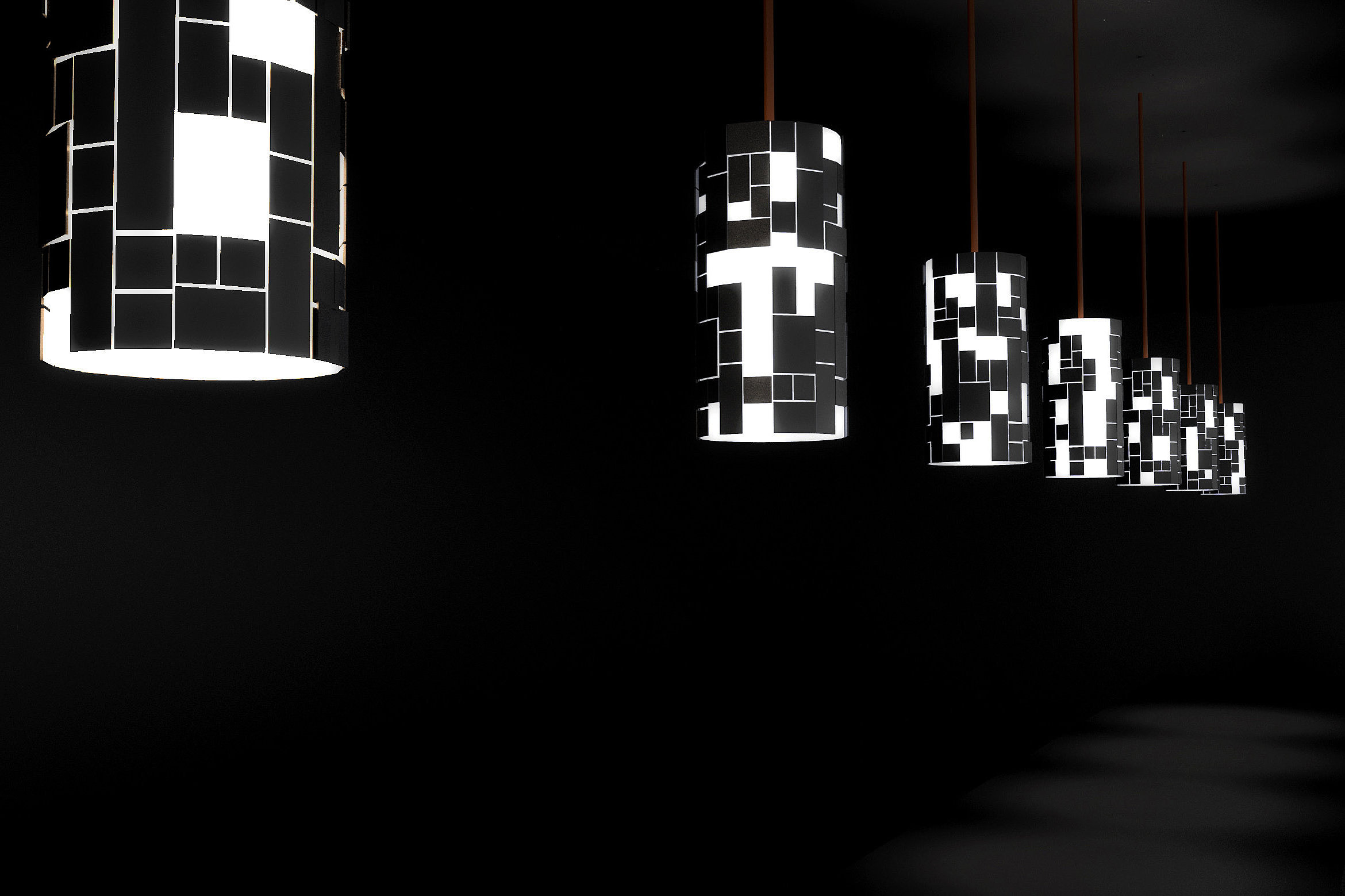

The Breakout Lamp

Additive manufacturing means design freedom for products that can be produced quickly and flexibly with any three-dimensional geometries. Like the Spiral Lamp, the “Breakout” bar lamp (PA) was developed from one surface into a fascinating 3D object. By breaking out parts, the optics of the lamp can be changed and an underlying layer inscribed with texts revealed. The only way that 1zu1 could realize this special lampshade design was via 3D printing on the company’s EOS 3D-printing systems.

Markus Schrittwieser: „We were involved in the poolbar project from the first idea to series production. New, creative solutions were found by scrutinizing each sample part. The optimal combination of design processes, technical optimizations and economic efficiency provided an innovative boost.“

poolbar festival 2016 and will be presented to a professional audience at the AM Expo in Lucerne in September – at the 1zu1 Prototypes exhibition stand. Further interesting details about this AM project can be found in our Customer story.

With 1zu1 as your AM project partner, you benefit from our vast 3D-printing expertise. Learn about the advantages this entails and make an appointment with your personal 1zu1 consultant.

![[Translate to English:] 3D printing](/fileadmin/_processed_/e/3/csm_20220310_DAT_0323_1200Px_3bfc482c6c.jpg)

![[Translate to English:] Production](/fileadmin/_processed_/2/c/csm_20200910_DAT_1012_v3-1_b0b1c6d9e5.jpg)

![[Translate to English:] Selective Laser Sintering (SLS)](/fileadmin/_processed_/e/c/csm_1zu1-Ameise-Header_b3d4651210.jpg)