Heads up: injection molding in a cleanroom!

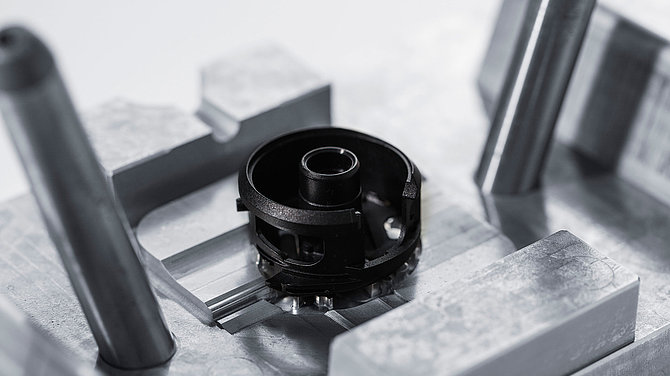

The expansion of the injection-molding shop at our Dornbirn site to include Class 8 cleanroom modules marks a decisive step forward for our business. Especially in the highly innovative sectors of microelectronics, medical technology and life science – and increasingly in many other industries as well – the demand for sterile products is growing amid increasing requirements for quality and reliability.

If you need prototypes or pre-series parts that comply with a cleanroom class as early as the product development phase, you will benefit significantly from 1zu1’s know-how. Manufactured in a cleanroom and protected by sterile packaging – and always at the usual rapid speed.

Not a speck of dust in sight!

We guarantee the highest levels of cleanliness by means of sophisticated filter technology, laminar-flow areas during workpiece removal and packaging, as well as constant monitoring. Our employees are subject to strict hygiene regulations and wear sterile work suits, hair nets and mouth protection. On request, we verify the cleanliness of our facility via contact sampling, which allows us to measure the bacterial load on surfaces. Of course, we pack your sterile products with primary and secondary functions in accordance with your packaging instructions.

Our ISO Class 8 injection-molding machines are housed in a separate room which cannot be seen from other areas. This means we can also fine-tune or sample your conventionally manufactured prototypes (i.e. without cleanroom class requirements) in total secrecy.

Everything is possible

Our combination of short production and delivery times, prototypes for all pre-series phases, manageable costs and top quality gives you a decisive edge during testing or market launch of your sterile products.

Finding technically clean solutions for our customers, even under difficult conditions, is our passion. We would be happy to walk you through all the available options during a comprehensive consultation. Learn about the new opportunities and make an appointment with your personal consultant at 1zu1.

We wish you a successful start to the New Year 2016!

![[Translate to English:] Cleanroom production in accordance with ISO Class 8](/fileadmin/_processed_/c/d/csm_1zu1-Spritzguss-Reinraum2_fbc95a434a.jpg)