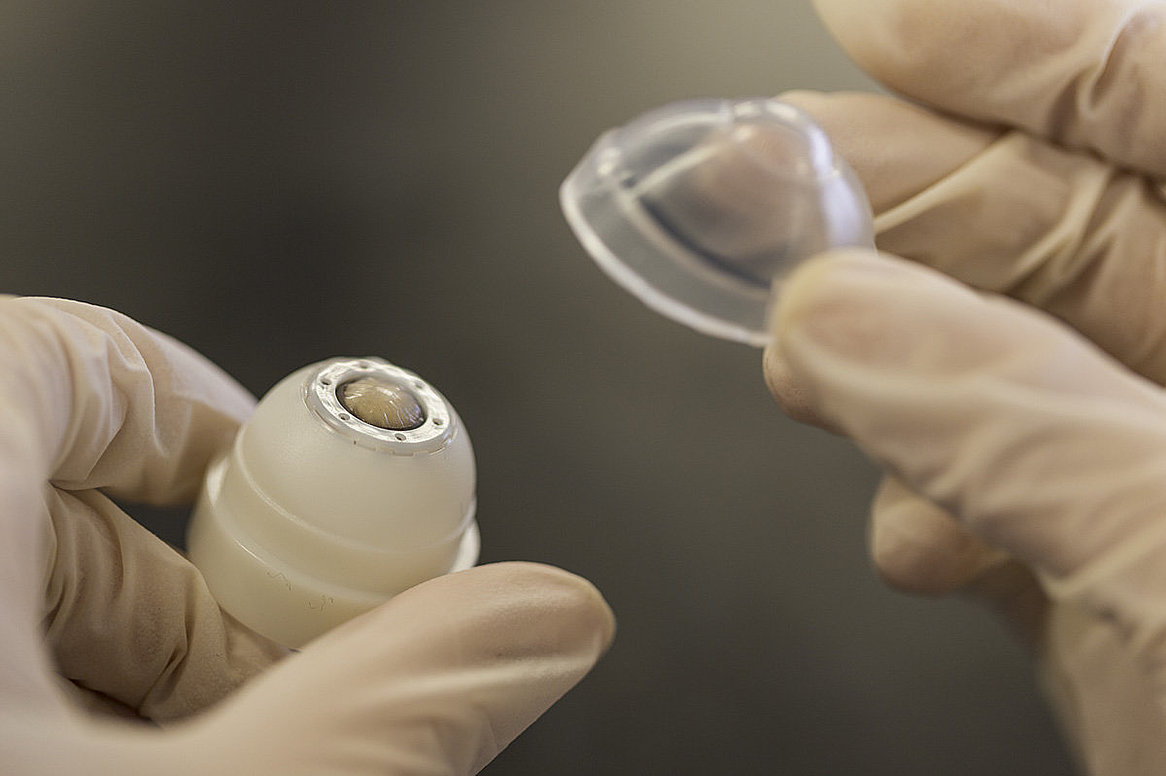

1zu1 loves a challenge! When David Ortner came to us in Dornbirn in 2013 with a few design drawings, we were instantly inspired by his idea: an artificial eye as a training tool for medical professionals. The complexity of the project was undeniable, but 1zu1 succeeded in bringing Ortner's product to market maturity. Ortner's company eyecre.at has since commissioned the production of over 10,000 artificial eyes. Its customers are located all around the world: at universities, conferences and large pharmaceutical companies.

Asking the right questions

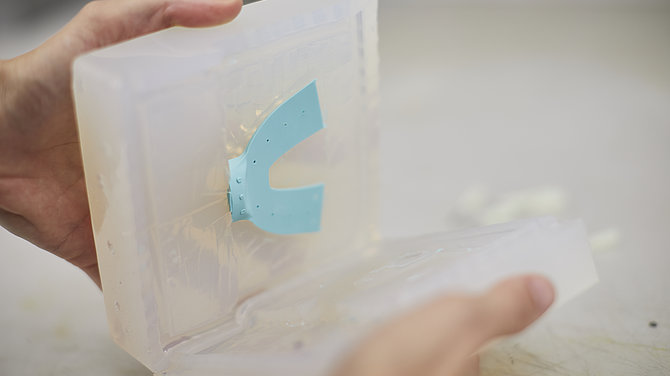

Right from the first meeting with the Tyrolean start-up entrepreneur, 1zu1 brought in a design engineer, as this was clearly not just a matter of producing a few parts. It was the company's deep understanding of the requirements and its excellent advice that really got the project off the ground, David Ortner recalls. Months of intensive cooperation followed. The first specimens of the lens, cornea and eye were created as stereolithography parts. The frame of the eye was produced from the material Accura Xtreme, while Waterclear Ultra was used for the lens and cornea. 1zu1 reduced the layer thickness from 0.1 to 0.05 millimeters to create a structure with more lifelike details.

At the end of the development phase we produced our first 20 eye, cornea and lens units. The eyes were produced once again by stereolithography, but this time using the material Accura 25. This is softer and comes close to the milky white color of the eyeball. This meant the parts no longer needed to be painted. In the case of the cornea and lens, a transparent PU resin, which has polycarbonate-like properties, was used for vacuum casting.

From prototype to series

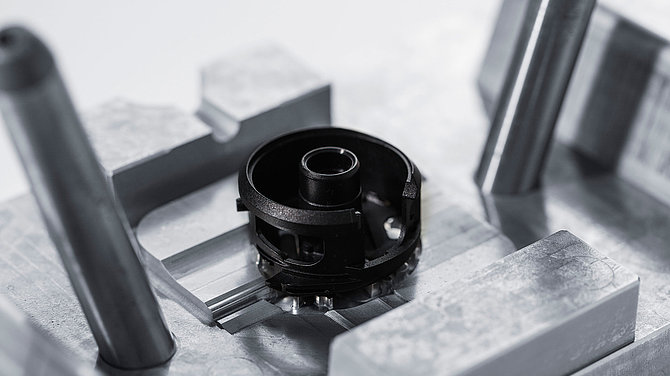

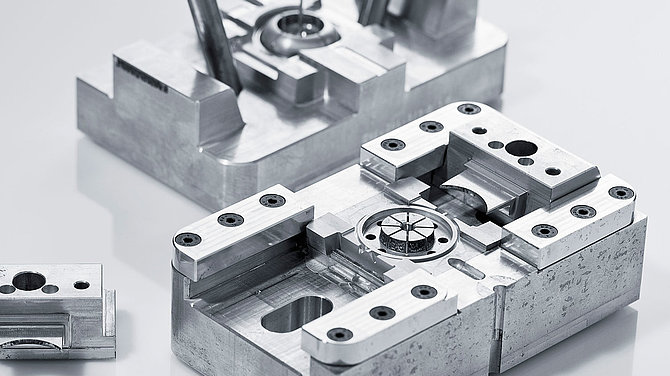

One of 1zu1's greatest strengths is its technological diversity. For the first substantive series production orders, we switched from stereolithography and vacuum casting to injection-molded in order to produce the fixing ring, support frame and base. All the other components are produced in-house by eyecre.at – and still by hand.

For the injection-molded parts we used aluminum tools, which yield an output of up to 30,000 parts - a perfectly adequate quantity for a project of this scale and a low-cost alternative to steel tools. Also, the fact that we use exchangeable, modular-style inserts for the tools rapid tooling in the Rapid Tooling department.

The launch of series production was a milestone for David Ortner. He now sells the artificial eyes all over the world. His customers include universities in Ulm, Heidelberg and Vienna, King Abdulaziz University in Saudi Arabia and large pharmaceutical companies such as Novartis and Bayer. And the problem-solvers at 1zu1 are equally proud of the global impact of the joint project.

Thanks to comprehensive 1zu1 know-how, an idea is turned into a success story. We can always be relied on for technological excellence and top quality. Why not make an appointment with your personal 1zu1 consultant and judge for yourself?

![[Translate to English:] Operation: Kunststoff-Auge [Translate to English:] Operation: Kunststoff-Auge](/fileadmin/_processed_/3/3/csm_Operation_2_dad93cc972.jpg)

![[Translate to English:] Stereolithography (STL/SLA)](/fileadmin/_processed_/a/5/csm_1zu1-STL-Duese-prozess_2ff0afbb81.jpg)