What we stand for

High Precision. Quick Solutions.

Production and prototyping of plastic parts - that is the world of 1zu1. For over 25 years. We operate in a wide variety of markets and work for national and international clients. With technological diversity as well as industry-leading precision and speed, we enable our customers to gain the decisive competitive edge.

Welcome to the world of 3D objects!

What solutions can we offer for your project?

See more We offer state-of-the-art, light-flooded workplaces with a view of the mountains around Dornbirn, a friendly team, thorough training, real opportunities for advancement, the innovative world of 3D objects, fair pay and extras such as pension plans and our own canteen.

Design opportunities are the greatest joy in the profession. We also support each individual with the freedom that makes top performance possible in the first place.

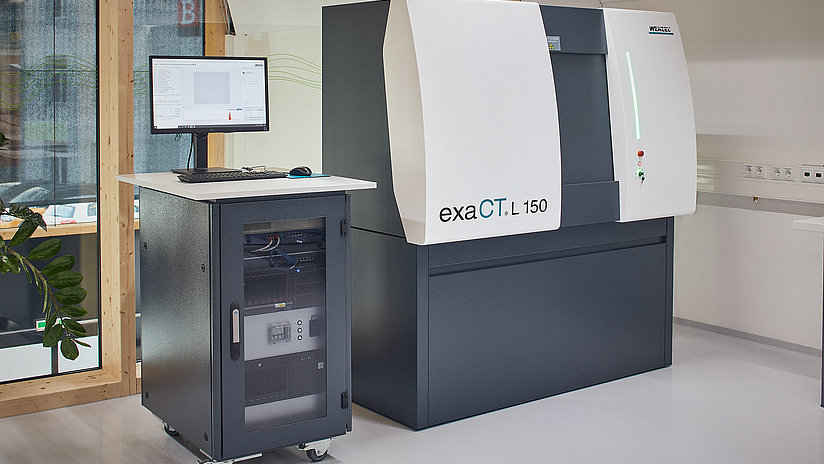

As demonstrated by our robotic milling center, which combines two state-of-the-art 5-axis HSC systems, we are constantly investing in new machines and processes. To master these is a daily challenge. All the better when everything runs smoothly.

We are an owner-managed high-tech company and celebrated our 25th anniversary in 2021 . “We plan for the long term and invest in people and machines, because technology without human know-how is pointless.” Our employees are our success factors.

Innovations don't happen by themselves. People try things out, experiment and look for solutions. Craftsmanship is required and the willingness to break new ground.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/d/csm_1zu1-Spritzguss-Reinraum2_eaf7711bca.jpg)