Selective Laser Sintering (SLS) is typically used for components with hard-to-reach areas, functional film hinges and undercuts. To enable us to manufacture these objects precisely and without problems, we have compiled a series of technical guidelines to support your design process. These design guidelines serve as a rough orientation and help to arrive at the final component by means of trial and error and the use of prototyping .

| EOS Formiga P110FDR | EOS Formiga P110 | EOS P396 | EOS P500 | |

|---|---|---|---|---|

|

Maximum recommended component dimensions | 40x40x40 mm | 100x100x100 mm | 300x300x600 mm | 300x300x450 mm |

|

System construction space | 200x250x100 mm | 200x250x330 mm | 350x350x620 mm | 330x400x500 mm |

| Minimum wall thickness | 0,22 mm (x, y) 0,12 mm (z) | 0.4 mm (x, y) 0.3 mm (z) | 0.6 mm (x, y) 0.3 mm (z) | 0.5 mm (x, y) 0.3 mm (z) |

| Minimum gap size Smaller gap widths are not shown. In the case of significantly thicker walls or complex geometries, it is advisable to produce the component cut-out beforehand and adapt the design as necessary. | ||||

| Wall thickness < 2 mm | 0,4 mm | 0.4 mm | 0.7 mm | 0.5 mm |

| Wall thickness 2 to 5 mm | not recommended | 0.6 mm | 0.8 mm | 0.6 mm |

|

Minimum bar diameter D as a function of the bar length l | D = 0.5 x l | D = 0.5 x l | D = 0.8 x l | D = 0.5 x l |

| PA2200 and PA3200GB | PP | |

|---|---|---|

| Tolerance with edge length ≤ 100 mm | ± 0.2 mm | ± 0.2 mm |

| Tolerance with edge length > 100 mm | ± 0.2 % | ± 0.3 % |

The PA1101 material is used in our Fine Detail Resolution (FDR) technology. The tolerance field TG5 according to DIN 16742 can be achieved with this technology as standard from the very first component. We can guarantee you the tolerance group TG4 according to DIN 16742 if you optimize components and process together with 1zu1 in iteration steps.

| Tolerance groups | 1 to 3 mm | > 3 to 6 mm | > 6 to 10 mm | > 10 to 18 mm | > 18 to 30 mm | > 30 to 50 mm |

| TG4 | +- 0,05 | +- 0,08 | +- 0,09 | +- 0,11 | +- 0,13 | +- 0,15 |

| TG5 | +- 0,08 | +- 0,11 | +- 0,14 | +- 0,17 | +- 0,20 | +- 0,23 |

SLS-rubber:

- Maximum component dimensions: 190 x 240 x 300 mm

- Minimum wall thickness: 0.8 mm

- The properties do not correspond to the usual rubber compounds.

- Due to the elasticity of the material, it is only possible to check the dimensional accuracy to a limited extent, depending on the geometry.

depend on the wall thickness of the component

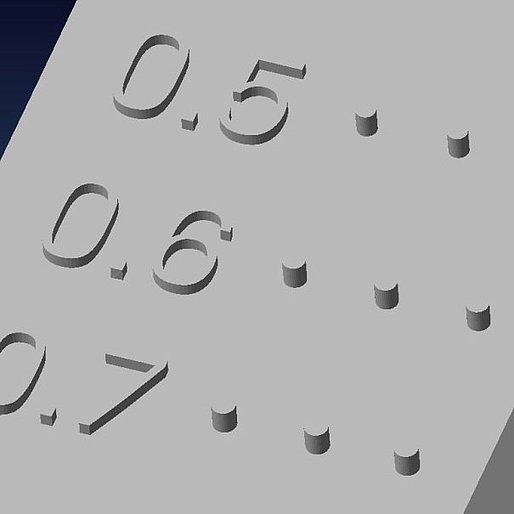

| Wall thickness | Hole diameter |

|---|---|

| 0.3 mm | 0.6 mm |

| 0.6 mm | 0.7 mm |

Additional design guidelines

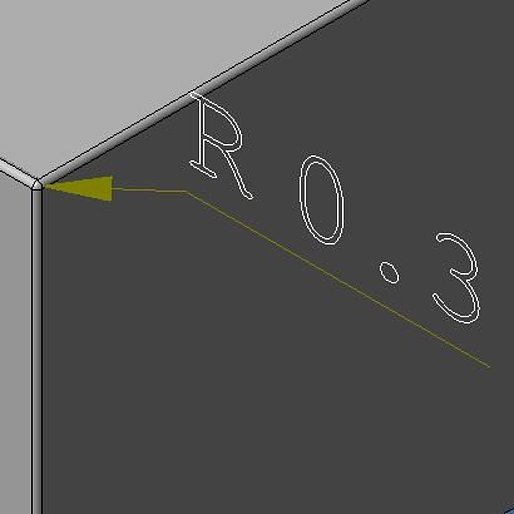

- Sharp corners and edges are not possible, the minimum radius is 0.3 mm. In exceptional cases, sharp edges are possible in the X/Y plane.

- In the case of very dense/solid components, bubbles may form within the parts due to the amount of energy applied.

- Powder removal must be possible (no completely closed cavities; difficulties arise with thin, curved and long pipes or narrow nozzles that are less than 1.5 mm in diameter).

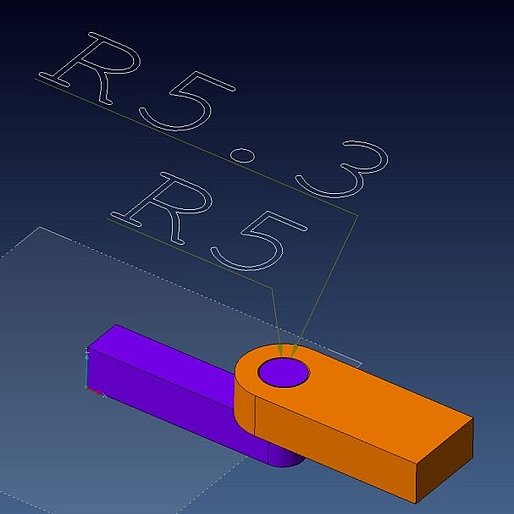

- Minimum gap (measured as radius) for joints: 0.3 mm. Pay attention to the hinge design (size and shape of the contact surface)! In the case of very solid joints, the required minimum gap dimension may also be (or even above) 1 mm. In case of doubt, consult the 1zu1 Prototypes team (at the RP Center).

- The minimum font size that can be easily imaged is 12 pt (equivalent to a height of 2.8 mm). Ideally, the font should be raised by 0.58 mm.

- For components intended for subsequent assembly, a dimensional difference of at least 0.3 mm must be constructed on the contact surfaces, otherwise a press fit will occur. See the information about component tolerances! Oversizes and subsequent mechanical processing (e.g., tapped holes or bolts) are possible.

- Separation of components with a wall thickness greater than 2.4 mm is possible; the components can be reassembled after manufacture (bonding of tongue and groove). We recommend consulting the 1zu1 Prototypes team to check feasibility with regard to the quality, dimensional accuracy, stability and the optimal solution for the joints.

- Many surfaces on one component/assembly – when used as a dummy, we recommend the creation of an enveloping surface with a wall thickness of 4 mm.

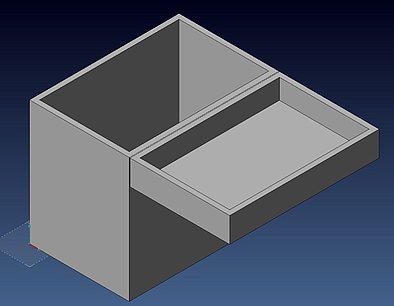

- In practice, a large number of possibilities can be reproduced on our PA 2200 and PP Formiga boxes

Application case for film hinge

possible with PA1101, PA2200 and PP

- Wall thickness 0.3-0.45 mm, consider length of the slat for minimum radius (with calculation based on neutral fiber).

- If several film hinges are required, they should, if possible, be oriented in the same plane or parallel to it.

- Due to their stability, film hinges are preferably attached to much thicker walls.

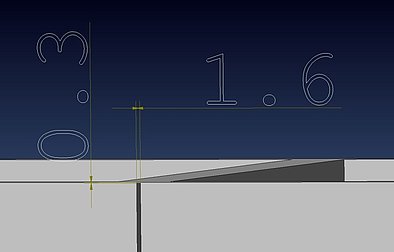

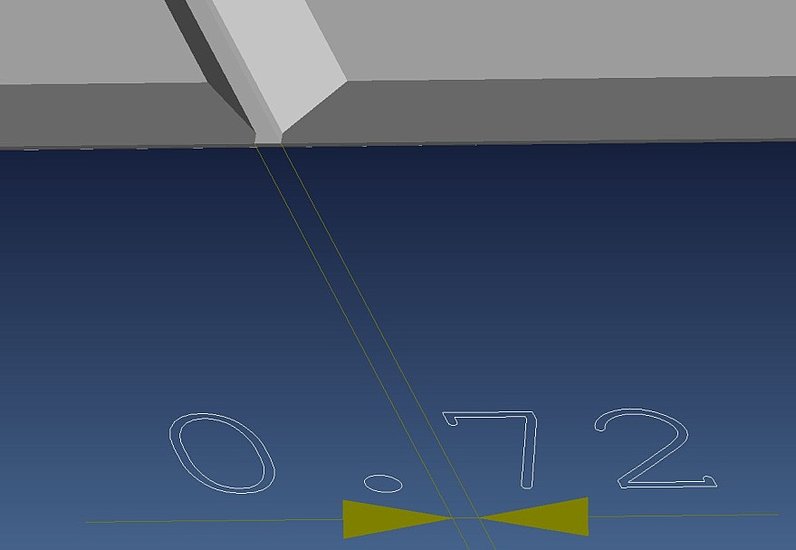

- Components with film hinges feature an open design. The hinge is then a flat surface. The distance between the components corresponds to the neutral fiber of the hinge with a minimum radius of 0.5 mm, e.g.

- Opening angle for hinge: 180 ° -> Distance: 1.6 mm

- Opening angle for hinge: 90 ° -> Distance: 0.72 mm

- Paired film hinges with preload are not sufficiently durable.

Advice tailored to your needs

At 1zu1, we help you find the perfect solution by combining the best technology with a wide range of materials. And this is implemented in the shortest possible time and with the highest technical precision. However, if you have any questions, please do not hesitate to contact me.

Markus Schrittwieser

1zu1innovation

innovation + development

T +43 5572 33 333-881

markus.schrittwieser@1zu1.eu

3D printing is constantly climbing new peaks!