3D metrology

Quality assurance and digitization

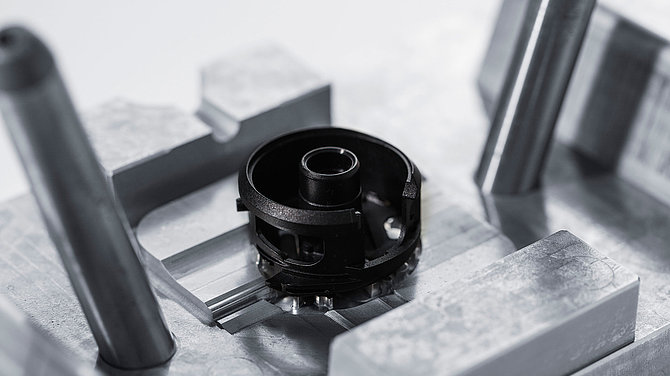

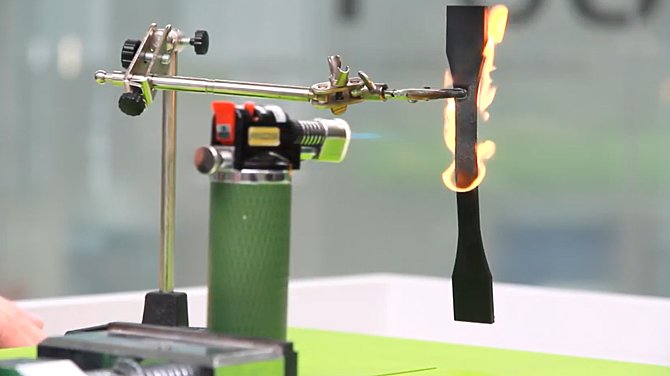

Whether digitization, prototyping, reverse engineering or quality control, our innovative 3D measurement technology is the basis for high-precision component detection and testing. Comparison images show deviations between the original data set and the component in just a few seconds. Test reports complete your documentation.

![[Translate to English:] Selective Laser Sintering (SLS)](/fileadmin/_processed_/e/c/csm_1zu1-Ameise-Header_b3d4651210.jpg)

![[Translate to English:] Selective Laser Sintering flexible (SLS)](/fileadmin/_processed_/c/5/csm_20230607_DAT_0001_Original_5d31893bd8.jpg)

![[Translate to English:] Stereolithography (STL/SLA)](/fileadmin/_processed_/a/5/csm_1zu1-STL-Duese-prozess_2ff0afbb81.jpg)

![[Translate to English:] Mechanical manufacturing (CNC)](/fileadmin/_processed_/3/c/csm_1zu1-MechanischeFertigung-Bauteile1_1b16c9709a.jpg)

![[Translate to English:] Lackieren, Strukturieren, Infiltrieren, Prägen, Bedrucken - vielfältige Druckdienstleistungen bei 1zu1 [Translate to English:] Lackieren, Strukturieren, Infiltrieren, Prägen, Bedrucken - vielfältige Druckdienstleistungen bei 1zu1](/fileadmin/_processed_/d/f/csm_1zu1-Oberflaeche-Spritzkitten_6314abec23.jpg)